Electronic Starter for Single Phase Motor. A Computational Efficient Algorithm for the Design of a Line Start Synchronous Motor with Multi-Segment Magnet Rotor. By Yannis L Karnavas and Ioannis D Chasiotis. Control strategies for interior type permanent magnet synchronous motor are discussed in detail in this Using damper winding 3. The main difference between a permanent magnet synchronous motor (PMSM) and an induction motor is in the rotor. When the stator of the motor is switched on,the stator flux starts revolving at synchronous speed but the rotor that is excited fails to catch up to a high speed and it begins t View the full answer The structural parameters of the An induction motor type SH-71-4a, available in commercial o ers, was adopted to build the prototype of the LSPMSM. The main difference between a permanent magnet synchronous motor (PMSM) and an induction motor is in the rotor.Studies 1 show that the PMSM has an efficiency of approximately 2% more than a highly efficient (IE3) induction electric motor, provided that the stator has the same design, and the same variable frequency drive is used for control. Takes a low pressure low temp vapor compresses it into a high pressure, high temp vapor.

A medium voltage VFD can sometimes resolve this issue. d. starting winding is not provided on the machines.

Once the synchronous speed is reached, the pony motor is decoupled and the DC excitation is given to the rotor. this is the most used method of starting synchronous motor.in addition to the normal field winding an additional winding consisting of copper bars placed in the slots in the pole faces.ends of the copper bars are short circuited with the help of end rings.this winding is called damper winding.this damper winding acts as a squirrel cage rotor of

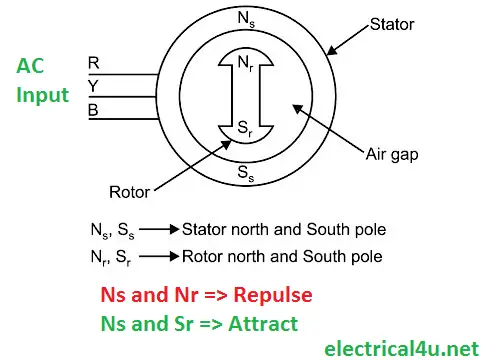

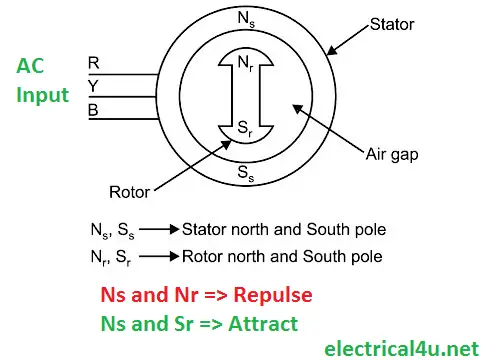

Once the synchronous speed is reached, the pony motor is decoupled and the DC excitation is given to the rotor. this is the most used method of starting synchronous motor.in addition to the normal field winding an additional winding consisting of copper bars placed in the slots in the pole faces.ends of the copper bars are short circuited with the help of end rings.this winding is called damper winding.this damper winding acts as a squirrel cage rotor of  1. The induction motor does not require an excitation system to start motor. The PMSM is a cross between an induction motor and brushless DC motor. In this article we discuss the working of a soft starter for synchronous motor.The soft starter, which is electronic voltage controller is also called an energy manager. Studies 1 show that the PMSM has an efficiency of approximately 2% more than a highly efficient (IE3) induction electric motor, provided that the stator has the same design, and the same variable frequency drive is used for control. . Synchronous motors are also used in voltage regulation. Enter the email address you signed up with and we'll email you a reset link. If a three phase supply is given to the stator of a three phase. Examples cited include pump motors, refiner motors for pulp and paper production, compressor motors for air separation, fans, blowers, extruders, and steam/gas turbine-driven generators. Practice #2 Inspection should be performed on a sample of HV machines, concentrating on those with the highest number of starts. Unlike an induction motor, the synchronous motor is excited by an external DC source and, therefore, requires slip rings and brushes to provide current to the rotor. Though battery-powered quartz regulated clocks are widely available, the AC line operated variety has better long term accuracyover a period of months. available with two types of gearboxes. This soft starter can This method is based on the principle that in star connections, the voltage across each winding is phase voltage i.e. 1. The basic concept is that the three-phase stator currents are controlled by three distinct hysteresis comparators. Figure 7 shows a typical starting curve for a 72 rpm SLO-SYN motor. The damper winding is an additional winding included on the rotor side. PARAMETER Cooling air70m/min Rated Efficiency91%. An over-excited synchronous motor works as a synchronous condenser when connected in parallel with a load having a lagging power factor, which improves the power factor of the combined load. The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. Starting as an induction motor and run as a synchronous motor. The three main ways are: Reduce frequency of stator to a safe starting level. Electric AC Motors Market Size To Reach USD 166.5 Billion by 2026 - The global electric AC motors market is estimated to reach USD 166.5 billion by 2026 growing at a CAGR of 8.8% during the forecast period, according to a new study published by Polaris Market Research. As seen earlier, synchronous motor is not self starting. It is necessary to rotate the rotor at a speed very near to synchronous speed. This is possible by various method in practice. The various methods to start the synchronous motor are, Three phase induction motors are commonly used in submersible motor applications. An icon used to represent a menu that can be toggled by interacting with this icon. Name 5 types of compressors. View Full-Text. The motor is cheap, especially cage rotors and maintenance-free. A synchronous motor installed at the receiving end substation operates with such an excitation that it takes power at lagging power factor. The Synchronous Motor requires the DC excitation system (or prime mover) to start the motor (i.e. Thorens TD160S 110V AC Synchronous Motor. A linear synchronous motor (LSM) is a linear motor in which the mechanical motion is in synchronism with the magnetic field, i.e., the mechanical speed is the same as the speed of the traveling magnetic field (Figure 3). Capacitor Start Capacitor Run. The synchronous motor is used for converting the electrical energy into mechanical energy. Turntable Motor Noise and Vibration. The LSPMM combines the advantages of the IM (robust construction and line-starting capability) and PM motor (high-efficiency, power factor, and torque density). In some cases, permanent magnets are used on the rotor of a synchronous machine to create the field. AC Synchronous motor 15Kg. Single-phase synchronous motors are available in small sizes for applications requiring precise timing such as timekeeping, (clocks) and tape players. The synchronous speed is the constant speed at which the motor generates the electromotive force. A synchronous motor is one in which the rotor normally rotates at the same speed as the revolving field in the machine. Therefore, the net torque developed in the rotor is zero. A winding consisting of heavy copper bars is 2-pole 500kW to 25MW, Cylindrical Rotors, 6.6kV 15kV, 50/60Hz. Two methods of proportional integral (PI) control are also used: stationary frame PI control and synchronous rotating frame PI control. A stator for the serially manufactured low-power induction motor was used. They differ from each other in: c starting current and torque values; c speed variation in normal operation; c power factor and efficiency values as a function of load. In this 2. Synchronous motors from the worlds leading supplier (vertical mounting available for motors with eight or more poles). The permanent magnets enable the PMSM to generate torque at zero speed. Various optimization techniques have been implemented in the optimization of the magnet thickness, magnet width or the rotor slots at line-start synchronous motors with hybrid magnets (combination of two types of magnet materials) or the line-start synchronous motor with a configuration of magnets with radial flux distribution [15,16,17]. In the synchronous motor, the rotor locks into step with the rotating magnetic field and rotates at synchronous speed. The robust frame transfers dynamic and static (and fixed speed motors with LCI starting) the field winding is AC fed. Basically, there are two methods for starting synchronous motors: Induction motor starting (Damper winding) Auxiliary motor starting. When the motor is brought to synchronous speed, AC current is applied to the stator windings. alternator, it can work as a motor. Abstract. A finite elements software was used for determining motor design and performance, in addition to analytical methods. Geared Synchronous. At present, damper windings are most widely used method of starting a synchronous motor. As we all know that Synchronous motors cannot self-start as it has no starting torque. synchronous motor starts to rotate if rotor catches the rotating magnetic field which rotates in synchronous speed. 4-pole 250kW to 60MW, Salient Pole Rotors, 400V 15kV, 50/60Hz. The motor is then started as an induction motor and brought to ~95% of synchronous speed, at which time direct current is applied, and the motor begins to pull into synchronism. Synchronous motors are. The ceramic rotor magnet material provides a relatively high flux resulting in a good torque-to-size ratio at moderate cost. For understanding in a given figure, the salient pole rotor with having 2 poles consists of damper windings is shown. The unusually short stopping What is the factor that enables the synchronous motor to operate at different electrical load characteristics? The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. for the rotor rotating). The motor will start and reach its full synchronous speed within 5 to 25 milliseconds. Using pony motors 2. Set 2 . advantages of a SLO-SYN motor. Vapor pump- It increases suction pressure level to the discharge pressure level. Features: Continuous Torque: 14.56 In-lbs. For example, they are used at the end of transmission lines to regulate voltage. In this method, the motor is started as a squirrel cage induction motor by providing a special winding on the rotor poles called damper winding. Synchronous motor belongs to AC class of motor which operates at a constant speed from no-load condition to full load condition. Using small d.c. machine coupled to it. Rotational speed: 534 rpm - 2,268 rpm. Now you understand that how the net torque developed in the motor is zero. 3. A soft starter is a electronic starter for synchronous motor which supplies gradually increasing voltage to the motor during start up to avoid high starting current taken by the motor. Synchronous Motors solved MCQs. A Damper Winding consists of heavy copper bars inserted in the slots of the pole faces of the rotor as shown in the figure below. A synchronous electric motor is an AC electric motor in which, at steady state, the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. B. the direction of instantaneous torque reverses after half cycle. Starting Methods of Synchronous Motor. What is the reason why a synchronous motor can be found running at no load? The motor can work at lagging, unity, and leading power factors. For example, the PMSM is widely used in robotics, machine tools, actuators, and it is being considered in high-power applications such as industrial drives and vehicular propulsion. Description: The 60 Hz can-stack motors operate at synchronous speeds of 300 and 600 rpm. Keywords: line-start synchronous permanent magnet motor rotor topologies transient characteristics FEM Abstract: Line-start synchronous permanent magnet motor (LSSPMM) is being considered as a replacement or alternative to asynchronous squirrel-cage motor (AM) in constant speed applications. Now if the applied voltage of the synchronous motor goes down, the power factor of the synchronous motor will. 2- What techniques are available to Synchronous Motor Starting with Damper Windings. 2) Synchronous or Stepper motor frame size 3.4" & 4.2" (motor dia. Phase Advancer. So if alternator is run as a. motor. Methods of Starting of Synchronous Motor Motor starting with an external prime Mover: Synchronous motors are mechanically coupled with another motor. Synchronous motor starters have proven to be a maintenance headache at times. The load may now be placed on the synchronous motor. The rotor of an asynchronous motor on the industrial market in the IE2 efficiency segment has been remodeled in the study, resulting in an increase in motor efficiency from 85% to 91.8%. explain. The size, weight, and cost of the equivalent three-phase induction motor are quite high for power needs ranging from 35 kW to 2500 KW. A second method is to start the synchronous motor as an induction motor. A Synchronous Motor may be started by a DC motor on a common shaft. The focus has been on techniques to improve the efficiency of three phase induction motors (by far the most common motor used in industry) and to develop new, more efficient, motor types such as the permanent magnet synchronous motor (PMSM). External prime mover 2. The permanent-magnet synchronous machine (PMSM) drive is one of best choices for a full range of motion control applications. Synchronous Motor. Cm. Starting methods of synchronous motor. Because of this inertia of the rotor, it is not possible for a rotor to get in sync with the stators magnetic-field at the very instance power is applied. There are different methods to start the 1- motors, they are as follows: Split Phase or Resistance Start. 1 of 5. Phase advancer is a simple AC exciter which is connected on the main shaft of the motor and operates with the motors rotor circuit for power factor improvement. Like a brushless DC motor, it has a permanent magnet rotor and windings on the stator. Generally, the motor will start within 1-1/2 cycles of the applied frequency and will stop within 5 mechanical degrees. On the Mathematical Modeling of Line-Start Permanent Magnet Synchronous Motors under Static Eccentricity.

1. The induction motor does not require an excitation system to start motor. The PMSM is a cross between an induction motor and brushless DC motor. In this article we discuss the working of a soft starter for synchronous motor.The soft starter, which is electronic voltage controller is also called an energy manager. Studies 1 show that the PMSM has an efficiency of approximately 2% more than a highly efficient (IE3) induction electric motor, provided that the stator has the same design, and the same variable frequency drive is used for control. . Synchronous motors are also used in voltage regulation. Enter the email address you signed up with and we'll email you a reset link. If a three phase supply is given to the stator of a three phase. Examples cited include pump motors, refiner motors for pulp and paper production, compressor motors for air separation, fans, blowers, extruders, and steam/gas turbine-driven generators. Practice #2 Inspection should be performed on a sample of HV machines, concentrating on those with the highest number of starts. Unlike an induction motor, the synchronous motor is excited by an external DC source and, therefore, requires slip rings and brushes to provide current to the rotor. Though battery-powered quartz regulated clocks are widely available, the AC line operated variety has better long term accuracyover a period of months. available with two types of gearboxes. This soft starter can This method is based on the principle that in star connections, the voltage across each winding is phase voltage i.e. 1. The basic concept is that the three-phase stator currents are controlled by three distinct hysteresis comparators. Figure 7 shows a typical starting curve for a 72 rpm SLO-SYN motor. The damper winding is an additional winding included on the rotor side. PARAMETER Cooling air70m/min Rated Efficiency91%. An over-excited synchronous motor works as a synchronous condenser when connected in parallel with a load having a lagging power factor, which improves the power factor of the combined load. The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. Starting as an induction motor and run as a synchronous motor. The three main ways are: Reduce frequency of stator to a safe starting level. Electric AC Motors Market Size To Reach USD 166.5 Billion by 2026 - The global electric AC motors market is estimated to reach USD 166.5 billion by 2026 growing at a CAGR of 8.8% during the forecast period, according to a new study published by Polaris Market Research. As seen earlier, synchronous motor is not self starting. It is necessary to rotate the rotor at a speed very near to synchronous speed. This is possible by various method in practice. The various methods to start the synchronous motor are, Three phase induction motors are commonly used in submersible motor applications. An icon used to represent a menu that can be toggled by interacting with this icon. Name 5 types of compressors. View Full-Text. The motor is cheap, especially cage rotors and maintenance-free. A synchronous motor installed at the receiving end substation operates with such an excitation that it takes power at lagging power factor. The Synchronous Motor requires the DC excitation system (or prime mover) to start the motor (i.e. Thorens TD160S 110V AC Synchronous Motor. A linear synchronous motor (LSM) is a linear motor in which the mechanical motion is in synchronism with the magnetic field, i.e., the mechanical speed is the same as the speed of the traveling magnetic field (Figure 3). Capacitor Start Capacitor Run. The synchronous motor is used for converting the electrical energy into mechanical energy. Turntable Motor Noise and Vibration. The LSPMM combines the advantages of the IM (robust construction and line-starting capability) and PM motor (high-efficiency, power factor, and torque density). In some cases, permanent magnets are used on the rotor of a synchronous machine to create the field. AC Synchronous motor 15Kg. Single-phase synchronous motors are available in small sizes for applications requiring precise timing such as timekeeping, (clocks) and tape players. The synchronous speed is the constant speed at which the motor generates the electromotive force. A synchronous motor is one in which the rotor normally rotates at the same speed as the revolving field in the machine. Therefore, the net torque developed in the rotor is zero. A winding consisting of heavy copper bars is 2-pole 500kW to 25MW, Cylindrical Rotors, 6.6kV 15kV, 50/60Hz. Two methods of proportional integral (PI) control are also used: stationary frame PI control and synchronous rotating frame PI control. A stator for the serially manufactured low-power induction motor was used. They differ from each other in: c starting current and torque values; c speed variation in normal operation; c power factor and efficiency values as a function of load. In this 2. Synchronous motors from the worlds leading supplier (vertical mounting available for motors with eight or more poles). The permanent magnets enable the PMSM to generate torque at zero speed. Various optimization techniques have been implemented in the optimization of the magnet thickness, magnet width or the rotor slots at line-start synchronous motors with hybrid magnets (combination of two types of magnet materials) or the line-start synchronous motor with a configuration of magnets with radial flux distribution [15,16,17]. In the synchronous motor, the rotor locks into step with the rotating magnetic field and rotates at synchronous speed. The robust frame transfers dynamic and static (and fixed speed motors with LCI starting) the field winding is AC fed. Basically, there are two methods for starting synchronous motors: Induction motor starting (Damper winding) Auxiliary motor starting. When the motor is brought to synchronous speed, AC current is applied to the stator windings. alternator, it can work as a motor. Abstract. A finite elements software was used for determining motor design and performance, in addition to analytical methods. Geared Synchronous. At present, damper windings are most widely used method of starting a synchronous motor. As we all know that Synchronous motors cannot self-start as it has no starting torque. synchronous motor starts to rotate if rotor catches the rotating magnetic field which rotates in synchronous speed. 4-pole 250kW to 60MW, Salient Pole Rotors, 400V 15kV, 50/60Hz. The motor is then started as an induction motor and brought to ~95% of synchronous speed, at which time direct current is applied, and the motor begins to pull into synchronism. Synchronous motors are. The ceramic rotor magnet material provides a relatively high flux resulting in a good torque-to-size ratio at moderate cost. For understanding in a given figure, the salient pole rotor with having 2 poles consists of damper windings is shown. The unusually short stopping What is the factor that enables the synchronous motor to operate at different electrical load characteristics? The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. for the rotor rotating). The motor will start and reach its full synchronous speed within 5 to 25 milliseconds. Using pony motors 2. Set 2 . advantages of a SLO-SYN motor. Vapor pump- It increases suction pressure level to the discharge pressure level. Features: Continuous Torque: 14.56 In-lbs. For example, they are used at the end of transmission lines to regulate voltage. In this method, the motor is started as a squirrel cage induction motor by providing a special winding on the rotor poles called damper winding. Synchronous motor belongs to AC class of motor which operates at a constant speed from no-load condition to full load condition. Using small d.c. machine coupled to it. Rotational speed: 534 rpm - 2,268 rpm. Now you understand that how the net torque developed in the motor is zero. 3. A soft starter is a electronic starter for synchronous motor which supplies gradually increasing voltage to the motor during start up to avoid high starting current taken by the motor. Synchronous Motors solved MCQs. A Damper Winding consists of heavy copper bars inserted in the slots of the pole faces of the rotor as shown in the figure below. A synchronous electric motor is an AC electric motor in which, at steady state, the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. B. the direction of instantaneous torque reverses after half cycle. Starting Methods of Synchronous Motor. What is the reason why a synchronous motor can be found running at no load? The motor can work at lagging, unity, and leading power factors. For example, the PMSM is widely used in robotics, machine tools, actuators, and it is being considered in high-power applications such as industrial drives and vehicular propulsion. Description: The 60 Hz can-stack motors operate at synchronous speeds of 300 and 600 rpm. Keywords: line-start synchronous permanent magnet motor rotor topologies transient characteristics FEM Abstract: Line-start synchronous permanent magnet motor (LSSPMM) is being considered as a replacement or alternative to asynchronous squirrel-cage motor (AM) in constant speed applications. Now if the applied voltage of the synchronous motor goes down, the power factor of the synchronous motor will. 2- What techniques are available to Synchronous Motor Starting with Damper Windings. 2) Synchronous or Stepper motor frame size 3.4" & 4.2" (motor dia. Phase Advancer. So if alternator is run as a. motor. Methods of Starting of Synchronous Motor Motor starting with an external prime Mover: Synchronous motors are mechanically coupled with another motor. Synchronous motor starters have proven to be a maintenance headache at times. The load may now be placed on the synchronous motor. The rotor of an asynchronous motor on the industrial market in the IE2 efficiency segment has been remodeled in the study, resulting in an increase in motor efficiency from 85% to 91.8%. explain. The size, weight, and cost of the equivalent three-phase induction motor are quite high for power needs ranging from 35 kW to 2500 KW. A second method is to start the synchronous motor as an induction motor. A Synchronous Motor may be started by a DC motor on a common shaft. The focus has been on techniques to improve the efficiency of three phase induction motors (by far the most common motor used in industry) and to develop new, more efficient, motor types such as the permanent magnet synchronous motor (PMSM). External prime mover 2. The permanent-magnet synchronous machine (PMSM) drive is one of best choices for a full range of motion control applications. Synchronous Motor. Cm. Starting methods of synchronous motor. Because of this inertia of the rotor, it is not possible for a rotor to get in sync with the stators magnetic-field at the very instance power is applied. There are different methods to start the 1- motors, they are as follows: Split Phase or Resistance Start. 1 of 5. Phase advancer is a simple AC exciter which is connected on the main shaft of the motor and operates with the motors rotor circuit for power factor improvement. Like a brushless DC motor, it has a permanent magnet rotor and windings on the stator. Generally, the motor will start within 1-1/2 cycles of the applied frequency and will stop within 5 mechanical degrees. On the Mathematical Modeling of Line-Start Permanent Magnet Synchronous Motors under Static Eccentricity.

Starting by using a dc motor coupled to the synchronous motor. The load may now be placed on the synchronous motor. The permanent magnet synchronous motors are AC synchronous motor whose field excitation is provided by permanent magnets and that has a sinusoidal back EMF waveform. On achieving synchronous speed, magnetic locking occurs, and the synchronous motor continues to rotate even after the removal of external mechanical means. 1) Synchronous or Stepper motor frame size 2.3" (motor dia. In my earlier post on turntable designs we took a look at the different drive techniques used to spin the platter. Engineering; Electrical Engineering; Electrical Engineering questions and answers; 1- Why can a synchronous motor not start by itself? Due to this zero torque, why synchronous motor cannot start itself. Meanwhile due to the rotor slight movement causes vibration in the motor for each electrical cycle and finally overheats. 86mm & 108mm) is coupled. Line-start synchronous reluctance motor(LS-SynRM) has the high efficiency than the induction motor that is almost used in the industrial application. It will rotate at a synchronous speed. This speed is achieved with the help of the rotating magnetic field produced by the stator winding. X s ( 2) Because the motor is a load on the system, both real and reactive power are referenced positively into the machine. The rotor of a synchronous motor behaves like permanent magnetic or electromagnetic and its field interacts with the stator field than it rotates at a time with the rotation of the stator field. Synchronous motors are generally not self-starting because. The most famous technique for starting of synchronous motor is to use an Amortisseur winding, it also is known as damper. Synchronous motors are generally not self-starting because. TERMS IN THIS SET (21) Describe the operation of a compressor. Torque. Definition: The motor which runs at synchronous speed is known as the synchronous motor. These copper bars are short-circuited by end rings at both ends of the rotor. Higher outputs available (starting & duty cycle dependent) High-Speed Synchronous Motors up to 25MW, 7200rpm. Synchronous motor is also known as the doubly feed because its rotor and stator both are connected with the spate inputs supply. Auxiliary Motor Start Using an auxiliary motor, the synchronous motor is first run as an alternator and is synchronised with the three-phase bus-bars. As is is driven at synchronous. The motor in Figure 1 has electromagnets on the rotor so a DC source is required to provide power to the coils. Damper winding 3. Single Phase Synchronous Motors.

(N s = 120f/P). The DC motor now acts as a DC generator and supplies DC field excitation to the rotor of the synchronous motor. Thus, these short-circuited Bars form a squirrel cage winding. As a simple method, a separate motor is used to drive the rotor to run close to the synchronous speed. Power: 291 kW. Starting with the help of a separate small induction motor. A synchronous motor is an AC electric motor that always rotates at a synchronous speed. Damper Winding Starting Most of the synchronous motors have a salient pole structure. Lets take a slightly more detailed look at the effects of the motor design that is used to drive the more popular belt drive turntables. Star Delta Starting Methods of Induction Motor. A small induction motor (or any other such motor, this motor is called pony motor) is used to start the synchronous motor, so that the synchronous motor begins to run. 58mm) is coupled with 80 x 73 x 17 mm gearbox. Once the speed reaches synchronous speed, three phase supply is switched on to the armature and excite the DC field winding from DC supply. The external motor is then decoupled and synchronous machine will work as a motor. At present this methods of starting is hardly used. ( 1) Q3 = 3 V 2 t V tEacos Xs (2) Q 3 = 3 V t 2 V t E a cos. . The rotor contains electromagnets, which create the field of the motor. The different methods used to start a synchronous motor are : Using Pony Motors : By using the small pony motors like a small induction motor, we can start the synchronous motor. The permanent magnets enable the PMSM to generate torque at zero speed. Synchronous motors are more often started by means of a squirrel-cage winding embedded in the face of the rotor poles. In this case, permanent magnet Damper Windings is the most widely used method to start a synchronous motor. Starting Methods of synchronous motor: Reduced frequency method External driver Method Using Induction motor Using a DC machine Using damper winding Slip ring assembly There are some techniques employed to start a synchronous motor. Features: Instant start, stop & Reversible, Low speed 60 RPM@50Hz.,High Torque 15.0 kg cm Insulation class - B. This small induction motor is coupled to the rotor of the synchronous motor. It depends on the supply frequency and the number of poles in the motor. Synchronous motor can started by the following three methods: 1. Linear electric motors can drive a linear motion load without intermediate gears, screws, or crank shafts. As a slip ring induction motor 4. HV motors are supplied with a voltage rarely exceeding 7.2 kV, their power Synchronous Motor Range. Using Resistor in the FieId Circuit

a. the direction of rotation is not fixed. A pole face with a set of damper winding is shown in given figure.

Advantages of Synchronous Motor : The power factor can be controlled easily. Practice #1 For selected drives without integral vibration probes, bearing vibration may be monitored at the prescribed interval using portable instruments, e.g. After synchronisation, supply to the auxiliary motor is cut, and the alternator is made to run as the synchronous motor drawing power from 3-phases AC mains. Capacitor Start. Due to its fixed speed characteristics, the synchronous motor is widely employed in industries. For starting a Synchronous motor, the line voltage is applied to the stator terminals with the field terminals (rotor) left unexcited. The Permanent Magnet Synchronous Motor (PMSM) is an AC synchronous motor whose field excitation is provided by permanent magnets and that has a sinusoidal back EMF waveform. By Ibrahem Hussein and Abdulaziz Milhem. Starting Methods of Synchronous Motor. Introduction. Step motors, dc brushless, variable reluctance motors, switched reluctance and hysteresis motors, and dc brush motors all typically operate as synchronous motors. Standard synchronous motors are available rated either 100% or 80% leading power factor. 5 Basic Questions on Synchronous Motor. A synchronous motor is one in which the rotor turns at the same speed as the rotating magnetic field in the stator. The motor is costly and requires frequent maintenance. An auxiliary device has to be used for this operation because synchronous motor has no self starting torque; It produces noise; 3. Starting using variable frequency External prime mover In this method, an external motor is coupled mechanically to the synchronous motor. A damper winding is made up of heavy copper bars inserted in slots cut into the pole faces of the rotor as shown in Figure-2. A commonly used method for controlling IM current loops is hysteresis control. A mechanical soft-start type coupling is used as an interface between a line start, synchronous motor and a heavy load to enable the synchronous motor to bring the heavy load up to or near synchronous speed. speed, it is called synchronous generator. Synchronous motors are commonly used for low speed, high power loads. Therefore different ways are used to start the motor. It is the most common starting method of synchronous motor. The equations that result for the synchronous motor are: P 3 = 3 V tEa Xs sin (1) P 3 = 3 V t E a X s sin. Current: 520 A - 650 A. Methods Of Starting Synchronous Motor 1. High-quality gearing is available for the can-stack motors. Synchronous motors are used in situations where the operating speed is low (about 500 rpm) but the power output is large. synchronous motor YZ141 series. Permanent magnet synchronous machines are gaining popularity because of their superior performance, high efficiency and energy density.Their applications are on the rise in industrial motor drives, variable speed wind turbine, electric vehicle, household equipment etc. 1000 V 625V air-cooled. Starting as an induction motor and run as a synchronous motor. 1/3 times the line voltage whereas the same winding, when connected in delta, will have full line voltage across it. The stator is similar to that of an induction machine consisting of a cylindrical iron frame with windings, usually three-phase, located in slots around the inner periphery. c. startes cannot be used on these machines. This motor is not self starting it requires some additional devices to start the motor. Pressure Solenoid Valve Design Synchronous Motor Centrifugal Compressor. This motor delivers high-efficiency operations and requires a digitally controlled inverter. These copper bars are then short-circuited by end rings at both ends of the rotor. DESCRIPTION YZ141AYZ141B is used in narrow gauge, and can be interchangeable with D29D31. These motors are mainly line-start permanent magnet motors (LSPMM). To explain this process in more detail, a variant of a single-phase synchronous motor - similar to the single-phase line start permanent magnet synchronous motor - has been simulated. Shock-Pulse-Meters for rolling-element bearings. Starting, Running & Stalling Currents are same. Damper Winding Starting Method. In a larger view, high-voltage motor technology would be suitable for any application where you find conventional synchronous machines today, he says. External force is used at start for bringing up the speed up to synchronous speed. The basic use of a synchronous motor is power factor correction that means to increase the power factor of a system. What is the typical speed regulation on a synchronous motor? It starts as an induction motor, and when it reaches a speed of about 95% of its synchronous speed, a weak d.c excitation is given to the rotor, thus making the rotor to align in synchronism with the stator. The aim of this paper was to design a low-power line-start synchronous motor. The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. The Permanent Magnet Synchronous Motor (PMSM) is an AC synchronous motor whose field excitation is provided by permanent magnets, and has a sinusoidal back EMF waveform. c asynchronous cage motors; c asynchronous slipring rotor motors; c synchronous motors. Permanent Split Capacitor. As a If damper winding is provided the motor will start like an induction motor and once if it reaches the nearby synchronous speed the synchronous motor will start to rotate in synchronous speed.

Electrical unbalance occurs when the magnetic attraction between stator and rotor is uneven around the periphery of the motor.This causes the shaft to deflect as it rotates creating a mechanical unbalance.Electrical unbalance usually indicates an electrical failure such as an open stator or rotor winding, an open bar or ring in squirrel cage motors or shorted field coils in The moment of inertia of rotor stops the large-sized synchronous motors from self-starting. Synchronous motors are available in sub-fractional self-excited sizes to high-horsepower direct-current excited industrial sizes. The report Electric AC Motors Market Share, Size, Trends, & Industry Analysis Report, By Type (Induction

Once the synchronous speed is reached, the pony motor is decoupled and the DC excitation is given to the rotor. this is the most used method of starting synchronous motor.in addition to the normal field winding an additional winding consisting of copper bars placed in the slots in the pole faces.ends of the copper bars are short circuited with the help of end rings.this winding is called damper winding.this damper winding acts as a squirrel cage rotor of

Once the synchronous speed is reached, the pony motor is decoupled and the DC excitation is given to the rotor. this is the most used method of starting synchronous motor.in addition to the normal field winding an additional winding consisting of copper bars placed in the slots in the pole faces.ends of the copper bars are short circuited with the help of end rings.this winding is called damper winding.this damper winding acts as a squirrel cage rotor of  1. The induction motor does not require an excitation system to start motor. The PMSM is a cross between an induction motor and brushless DC motor. In this article we discuss the working of a soft starter for synchronous motor.The soft starter, which is electronic voltage controller is also called an energy manager. Studies 1 show that the PMSM has an efficiency of approximately 2% more than a highly efficient (IE3) induction electric motor, provided that the stator has the same design, and the same variable frequency drive is used for control. . Synchronous motors are also used in voltage regulation. Enter the email address you signed up with and we'll email you a reset link. If a three phase supply is given to the stator of a three phase. Examples cited include pump motors, refiner motors for pulp and paper production, compressor motors for air separation, fans, blowers, extruders, and steam/gas turbine-driven generators. Practice #2 Inspection should be performed on a sample of HV machines, concentrating on those with the highest number of starts. Unlike an induction motor, the synchronous motor is excited by an external DC source and, therefore, requires slip rings and brushes to provide current to the rotor. Though battery-powered quartz regulated clocks are widely available, the AC line operated variety has better long term accuracyover a period of months. available with two types of gearboxes. This soft starter can This method is based on the principle that in star connections, the voltage across each winding is phase voltage i.e. 1. The basic concept is that the three-phase stator currents are controlled by three distinct hysteresis comparators. Figure 7 shows a typical starting curve for a 72 rpm SLO-SYN motor. The damper winding is an additional winding included on the rotor side. PARAMETER Cooling air70m/min Rated Efficiency91%. An over-excited synchronous motor works as a synchronous condenser when connected in parallel with a load having a lagging power factor, which improves the power factor of the combined load. The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. Starting as an induction motor and run as a synchronous motor. The three main ways are: Reduce frequency of stator to a safe starting level. Electric AC Motors Market Size To Reach USD 166.5 Billion by 2026 - The global electric AC motors market is estimated to reach USD 166.5 billion by 2026 growing at a CAGR of 8.8% during the forecast period, according to a new study published by Polaris Market Research. As seen earlier, synchronous motor is not self starting. It is necessary to rotate the rotor at a speed very near to synchronous speed. This is possible by various method in practice. The various methods to start the synchronous motor are, Three phase induction motors are commonly used in submersible motor applications. An icon used to represent a menu that can be toggled by interacting with this icon. Name 5 types of compressors. View Full-Text. The motor is cheap, especially cage rotors and maintenance-free. A synchronous motor installed at the receiving end substation operates with such an excitation that it takes power at lagging power factor. The Synchronous Motor requires the DC excitation system (or prime mover) to start the motor (i.e. Thorens TD160S 110V AC Synchronous Motor. A linear synchronous motor (LSM) is a linear motor in which the mechanical motion is in synchronism with the magnetic field, i.e., the mechanical speed is the same as the speed of the traveling magnetic field (Figure 3). Capacitor Start Capacitor Run. The synchronous motor is used for converting the electrical energy into mechanical energy. Turntable Motor Noise and Vibration. The LSPMM combines the advantages of the IM (robust construction and line-starting capability) and PM motor (high-efficiency, power factor, and torque density). In some cases, permanent magnets are used on the rotor of a synchronous machine to create the field. AC Synchronous motor 15Kg. Single-phase synchronous motors are available in small sizes for applications requiring precise timing such as timekeeping, (clocks) and tape players. The synchronous speed is the constant speed at which the motor generates the electromotive force. A synchronous motor is one in which the rotor normally rotates at the same speed as the revolving field in the machine. Therefore, the net torque developed in the rotor is zero. A winding consisting of heavy copper bars is 2-pole 500kW to 25MW, Cylindrical Rotors, 6.6kV 15kV, 50/60Hz. Two methods of proportional integral (PI) control are also used: stationary frame PI control and synchronous rotating frame PI control. A stator for the serially manufactured low-power induction motor was used. They differ from each other in: c starting current and torque values; c speed variation in normal operation; c power factor and efficiency values as a function of load. In this 2. Synchronous motors from the worlds leading supplier (vertical mounting available for motors with eight or more poles). The permanent magnets enable the PMSM to generate torque at zero speed. Various optimization techniques have been implemented in the optimization of the magnet thickness, magnet width or the rotor slots at line-start synchronous motors with hybrid magnets (combination of two types of magnet materials) or the line-start synchronous motor with a configuration of magnets with radial flux distribution [15,16,17]. In the synchronous motor, the rotor locks into step with the rotating magnetic field and rotates at synchronous speed. The robust frame transfers dynamic and static (and fixed speed motors with LCI starting) the field winding is AC fed. Basically, there are two methods for starting synchronous motors: Induction motor starting (Damper winding) Auxiliary motor starting. When the motor is brought to synchronous speed, AC current is applied to the stator windings. alternator, it can work as a motor. Abstract. A finite elements software was used for determining motor design and performance, in addition to analytical methods. Geared Synchronous. At present, damper windings are most widely used method of starting a synchronous motor. As we all know that Synchronous motors cannot self-start as it has no starting torque. synchronous motor starts to rotate if rotor catches the rotating magnetic field which rotates in synchronous speed. 4-pole 250kW to 60MW, Salient Pole Rotors, 400V 15kV, 50/60Hz. The motor is then started as an induction motor and brought to ~95% of synchronous speed, at which time direct current is applied, and the motor begins to pull into synchronism. Synchronous motors are. The ceramic rotor magnet material provides a relatively high flux resulting in a good torque-to-size ratio at moderate cost. For understanding in a given figure, the salient pole rotor with having 2 poles consists of damper windings is shown. The unusually short stopping What is the factor that enables the synchronous motor to operate at different electrical load characteristics? The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. for the rotor rotating). The motor will start and reach its full synchronous speed within 5 to 25 milliseconds. Using pony motors 2. Set 2 . advantages of a SLO-SYN motor. Vapor pump- It increases suction pressure level to the discharge pressure level. Features: Continuous Torque: 14.56 In-lbs. For example, they are used at the end of transmission lines to regulate voltage. In this method, the motor is started as a squirrel cage induction motor by providing a special winding on the rotor poles called damper winding. Synchronous motor belongs to AC class of motor which operates at a constant speed from no-load condition to full load condition. Using small d.c. machine coupled to it. Rotational speed: 534 rpm - 2,268 rpm. Now you understand that how the net torque developed in the motor is zero. 3. A soft starter is a electronic starter for synchronous motor which supplies gradually increasing voltage to the motor during start up to avoid high starting current taken by the motor. Synchronous Motors solved MCQs. A Damper Winding consists of heavy copper bars inserted in the slots of the pole faces of the rotor as shown in the figure below. A synchronous electric motor is an AC electric motor in which, at steady state, the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. B. the direction of instantaneous torque reverses after half cycle. Starting Methods of Synchronous Motor. What is the reason why a synchronous motor can be found running at no load? The motor can work at lagging, unity, and leading power factors. For example, the PMSM is widely used in robotics, machine tools, actuators, and it is being considered in high-power applications such as industrial drives and vehicular propulsion. Description: The 60 Hz can-stack motors operate at synchronous speeds of 300 and 600 rpm. Keywords: line-start synchronous permanent magnet motor rotor topologies transient characteristics FEM Abstract: Line-start synchronous permanent magnet motor (LSSPMM) is being considered as a replacement or alternative to asynchronous squirrel-cage motor (AM) in constant speed applications. Now if the applied voltage of the synchronous motor goes down, the power factor of the synchronous motor will. 2- What techniques are available to Synchronous Motor Starting with Damper Windings. 2) Synchronous or Stepper motor frame size 3.4" & 4.2" (motor dia. Phase Advancer. So if alternator is run as a. motor. Methods of Starting of Synchronous Motor Motor starting with an external prime Mover: Synchronous motors are mechanically coupled with another motor. Synchronous motor starters have proven to be a maintenance headache at times. The load may now be placed on the synchronous motor. The rotor of an asynchronous motor on the industrial market in the IE2 efficiency segment has been remodeled in the study, resulting in an increase in motor efficiency from 85% to 91.8%. explain. The size, weight, and cost of the equivalent three-phase induction motor are quite high for power needs ranging from 35 kW to 2500 KW. A second method is to start the synchronous motor as an induction motor. A Synchronous Motor may be started by a DC motor on a common shaft. The focus has been on techniques to improve the efficiency of three phase induction motors (by far the most common motor used in industry) and to develop new, more efficient, motor types such as the permanent magnet synchronous motor (PMSM). External prime mover 2. The permanent-magnet synchronous machine (PMSM) drive is one of best choices for a full range of motion control applications. Synchronous Motor. Cm. Starting methods of synchronous motor. Because of this inertia of the rotor, it is not possible for a rotor to get in sync with the stators magnetic-field at the very instance power is applied. There are different methods to start the 1- motors, they are as follows: Split Phase or Resistance Start. 1 of 5. Phase advancer is a simple AC exciter which is connected on the main shaft of the motor and operates with the motors rotor circuit for power factor improvement. Like a brushless DC motor, it has a permanent magnet rotor and windings on the stator. Generally, the motor will start within 1-1/2 cycles of the applied frequency and will stop within 5 mechanical degrees. On the Mathematical Modeling of Line-Start Permanent Magnet Synchronous Motors under Static Eccentricity.

1. The induction motor does not require an excitation system to start motor. The PMSM is a cross between an induction motor and brushless DC motor. In this article we discuss the working of a soft starter for synchronous motor.The soft starter, which is electronic voltage controller is also called an energy manager. Studies 1 show that the PMSM has an efficiency of approximately 2% more than a highly efficient (IE3) induction electric motor, provided that the stator has the same design, and the same variable frequency drive is used for control. . Synchronous motors are also used in voltage regulation. Enter the email address you signed up with and we'll email you a reset link. If a three phase supply is given to the stator of a three phase. Examples cited include pump motors, refiner motors for pulp and paper production, compressor motors for air separation, fans, blowers, extruders, and steam/gas turbine-driven generators. Practice #2 Inspection should be performed on a sample of HV machines, concentrating on those with the highest number of starts. Unlike an induction motor, the synchronous motor is excited by an external DC source and, therefore, requires slip rings and brushes to provide current to the rotor. Though battery-powered quartz regulated clocks are widely available, the AC line operated variety has better long term accuracyover a period of months. available with two types of gearboxes. This soft starter can This method is based on the principle that in star connections, the voltage across each winding is phase voltage i.e. 1. The basic concept is that the three-phase stator currents are controlled by three distinct hysteresis comparators. Figure 7 shows a typical starting curve for a 72 rpm SLO-SYN motor. The damper winding is an additional winding included on the rotor side. PARAMETER Cooling air70m/min Rated Efficiency91%. An over-excited synchronous motor works as a synchronous condenser when connected in parallel with a load having a lagging power factor, which improves the power factor of the combined load. The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. Starting as an induction motor and run as a synchronous motor. The three main ways are: Reduce frequency of stator to a safe starting level. Electric AC Motors Market Size To Reach USD 166.5 Billion by 2026 - The global electric AC motors market is estimated to reach USD 166.5 billion by 2026 growing at a CAGR of 8.8% during the forecast period, according to a new study published by Polaris Market Research. As seen earlier, synchronous motor is not self starting. It is necessary to rotate the rotor at a speed very near to synchronous speed. This is possible by various method in practice. The various methods to start the synchronous motor are, Three phase induction motors are commonly used in submersible motor applications. An icon used to represent a menu that can be toggled by interacting with this icon. Name 5 types of compressors. View Full-Text. The motor is cheap, especially cage rotors and maintenance-free. A synchronous motor installed at the receiving end substation operates with such an excitation that it takes power at lagging power factor. The Synchronous Motor requires the DC excitation system (or prime mover) to start the motor (i.e. Thorens TD160S 110V AC Synchronous Motor. A linear synchronous motor (LSM) is a linear motor in which the mechanical motion is in synchronism with the magnetic field, i.e., the mechanical speed is the same as the speed of the traveling magnetic field (Figure 3). Capacitor Start Capacitor Run. The synchronous motor is used for converting the electrical energy into mechanical energy. Turntable Motor Noise and Vibration. The LSPMM combines the advantages of the IM (robust construction and line-starting capability) and PM motor (high-efficiency, power factor, and torque density). In some cases, permanent magnets are used on the rotor of a synchronous machine to create the field. AC Synchronous motor 15Kg. Single-phase synchronous motors are available in small sizes for applications requiring precise timing such as timekeeping, (clocks) and tape players. The synchronous speed is the constant speed at which the motor generates the electromotive force. A synchronous motor is one in which the rotor normally rotates at the same speed as the revolving field in the machine. Therefore, the net torque developed in the rotor is zero. A winding consisting of heavy copper bars is 2-pole 500kW to 25MW, Cylindrical Rotors, 6.6kV 15kV, 50/60Hz. Two methods of proportional integral (PI) control are also used: stationary frame PI control and synchronous rotating frame PI control. A stator for the serially manufactured low-power induction motor was used. They differ from each other in: c starting current and torque values; c speed variation in normal operation; c power factor and efficiency values as a function of load. In this 2. Synchronous motors from the worlds leading supplier (vertical mounting available for motors with eight or more poles). The permanent magnets enable the PMSM to generate torque at zero speed. Various optimization techniques have been implemented in the optimization of the magnet thickness, magnet width or the rotor slots at line-start synchronous motors with hybrid magnets (combination of two types of magnet materials) or the line-start synchronous motor with a configuration of magnets with radial flux distribution [15,16,17]. In the synchronous motor, the rotor locks into step with the rotating magnetic field and rotates at synchronous speed. The robust frame transfers dynamic and static (and fixed speed motors with LCI starting) the field winding is AC fed. Basically, there are two methods for starting synchronous motors: Induction motor starting (Damper winding) Auxiliary motor starting. When the motor is brought to synchronous speed, AC current is applied to the stator windings. alternator, it can work as a motor. Abstract. A finite elements software was used for determining motor design and performance, in addition to analytical methods. Geared Synchronous. At present, damper windings are most widely used method of starting a synchronous motor. As we all know that Synchronous motors cannot self-start as it has no starting torque. synchronous motor starts to rotate if rotor catches the rotating magnetic field which rotates in synchronous speed. 4-pole 250kW to 60MW, Salient Pole Rotors, 400V 15kV, 50/60Hz. The motor is then started as an induction motor and brought to ~95% of synchronous speed, at which time direct current is applied, and the motor begins to pull into synchronism. Synchronous motors are. The ceramic rotor magnet material provides a relatively high flux resulting in a good torque-to-size ratio at moderate cost. For understanding in a given figure, the salient pole rotor with having 2 poles consists of damper windings is shown. The unusually short stopping What is the factor that enables the synchronous motor to operate at different electrical load characteristics? The methods most commonly used to bring the motor up to synchronous speed are: Starting with the help of a damper winding. Starting with the help of a separate small induction motor. Starting by using a dc motor coupled to the synchronous motor. for the rotor rotating). The motor will start and reach its full synchronous speed within 5 to 25 milliseconds. Using pony motors 2. Set 2 . advantages of a SLO-SYN motor. Vapor pump- It increases suction pressure level to the discharge pressure level. Features: Continuous Torque: 14.56 In-lbs. For example, they are used at the end of transmission lines to regulate voltage. In this method, the motor is started as a squirrel cage induction motor by providing a special winding on the rotor poles called damper winding. Synchronous motor belongs to AC class of motor which operates at a constant speed from no-load condition to full load condition. Using small d.c. machine coupled to it. Rotational speed: 534 rpm - 2,268 rpm. Now you understand that how the net torque developed in the motor is zero. 3. A soft starter is a electronic starter for synchronous motor which supplies gradually increasing voltage to the motor during start up to avoid high starting current taken by the motor. Synchronous Motors solved MCQs. A Damper Winding consists of heavy copper bars inserted in the slots of the pole faces of the rotor as shown in the figure below. A synchronous electric motor is an AC electric motor in which, at steady state, the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. B. the direction of instantaneous torque reverses after half cycle. Starting Methods of Synchronous Motor. What is the reason why a synchronous motor can be found running at no load? The motor can work at lagging, unity, and leading power factors. For example, the PMSM is widely used in robotics, machine tools, actuators, and it is being considered in high-power applications such as industrial drives and vehicular propulsion. Description: The 60 Hz can-stack motors operate at synchronous speeds of 300 and 600 rpm. Keywords: line-start synchronous permanent magnet motor rotor topologies transient characteristics FEM Abstract: Line-start synchronous permanent magnet motor (LSSPMM) is being considered as a replacement or alternative to asynchronous squirrel-cage motor (AM) in constant speed applications. Now if the applied voltage of the synchronous motor goes down, the power factor of the synchronous motor will. 2- What techniques are available to Synchronous Motor Starting with Damper Windings. 2) Synchronous or Stepper motor frame size 3.4" & 4.2" (motor dia. Phase Advancer. So if alternator is run as a. motor. Methods of Starting of Synchronous Motor Motor starting with an external prime Mover: Synchronous motors are mechanically coupled with another motor. Synchronous motor starters have proven to be a maintenance headache at times. The load may now be placed on the synchronous motor. The rotor of an asynchronous motor on the industrial market in the IE2 efficiency segment has been remodeled in the study, resulting in an increase in motor efficiency from 85% to 91.8%. explain. The size, weight, and cost of the equivalent three-phase induction motor are quite high for power needs ranging from 35 kW to 2500 KW. A second method is to start the synchronous motor as an induction motor. A Synchronous Motor may be started by a DC motor on a common shaft. The focus has been on techniques to improve the efficiency of three phase induction motors (by far the most common motor used in industry) and to develop new, more efficient, motor types such as the permanent magnet synchronous motor (PMSM). External prime mover 2. The permanent-magnet synchronous machine (PMSM) drive is one of best choices for a full range of motion control applications. Synchronous Motor. Cm. Starting methods of synchronous motor. Because of this inertia of the rotor, it is not possible for a rotor to get in sync with the stators magnetic-field at the very instance power is applied. There are different methods to start the 1- motors, they are as follows: Split Phase or Resistance Start. 1 of 5. Phase advancer is a simple AC exciter which is connected on the main shaft of the motor and operates with the motors rotor circuit for power factor improvement. Like a brushless DC motor, it has a permanent magnet rotor and windings on the stator. Generally, the motor will start within 1-1/2 cycles of the applied frequency and will stop within 5 mechanical degrees. On the Mathematical Modeling of Line-Start Permanent Magnet Synchronous Motors under Static Eccentricity.