-calculate resistance and check by measuring. - I recently added a small second solar panel to charge the car battery that operates my gate. -if motor has field winding (s) , look voltage and current values for field in name plate. DC, on the other hand, continues to undo their own history, even if it's just recently been established. 2,098. Any value greater 0.5 ohms indicate trouble with the motor.

1. In a shunt motor, the shunt field current Ish is always a constant since the field winding is connected in parallel to the armature winding and the supply voltage. you can get it as an example and do it with all types of motors like single-phase and three-phase. To test the continuity settings calibration, touch the 2 terminals together and hold them in place.

How to Test Continuity. Horn - should it have continuity? 1.Check the outside of the motor. Supply Test; If you have a 230/400V three-phase motor, the normal voltage value will be 230V between phase to neutral point, and 400V between supply lines. Remove the DC motor from its machine housing so the rotor can move freely during diagnostics. 1.  The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 /

The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 /  The windings (all three in a three-phase motor) should read low but not zero ohms. Touch one of the tester leads to one terminal and the other lead to the other terminal and check the reading. b. Jun 26, 2013. In other words, the higher the voltage, the quicker will the magnetic field become strong. A brushless motor should spin freely when all the wires are separated as there is not a complete circuit. Usuaully, with a large amount of turns (60 to 200+ turns) per field coil. How to Test and Troubleshoot Vacuum Circuit Boards. so the friend keeps watch and enjoy it.. 2.1 Motor Ohm Values Chart; 3 3 Phase Motor Winding; 4 3 Phase Motor Winding Resistance Step 4 Use Your Ears. Readings may run from .5 Since they are connected in parallel, the armature and field windings are exposed to the same supply voltage.Though there are separate branches for the I'm not sure but > I suppose that would make sense. Test the shunt field continuity by measuring and recording the A plain DC series motor will only have one pair of wires through the armature and field, a shunt will have two pairs of wires and a compound will have six wires, two for each circuit, The beep, an audible indicator, permits technicians to focus

The windings (all three in a three-phase motor) should read low but not zero ohms. Touch one of the tester leads to one terminal and the other lead to the other terminal and check the reading. b. Jun 26, 2013. In other words, the higher the voltage, the quicker will the magnetic field become strong. A brushless motor should spin freely when all the wires are separated as there is not a complete circuit. Usuaully, with a large amount of turns (60 to 200+ turns) per field coil. How to Test and Troubleshoot Vacuum Circuit Boards. so the friend keeps watch and enjoy it.. 2.1 Motor Ohm Values Chart; 3 3 Phase Motor Winding; 4 3 Phase Motor Winding Resistance Step 4 Use Your Ears. Readings may run from .5 Since they are connected in parallel, the armature and field windings are exposed to the same supply voltage.Though there are separate branches for the I'm not sure but > I suppose that would make sense. Test the shunt field continuity by measuring and recording the A plain DC series motor will only have one pair of wires through the armature and field, a shunt will have two pairs of wires and a compound will have six wires, two for each circuit, The beep, an audible indicator, permits technicians to focus  None of the leads has been field connected - that is, all leads are separated from each other. Huw Powell audi at humanspeakers.com Mon Feb 8 10:37:29 PST 2010. Check ohm's between both terminals, should have continuity, if so, check either terminal to metal housing of fan, if continuity exists, fan motor is bad. Motor Disassembly. If fuse one is blown you must replace all three fuses. ; 2 its a very easy way here to Know The Motor Ohm Values Chart & set up the coil size of the motor. This results in an increase in no-load speed and a The continuity of the post Rebirth/Metal/Doomsday Clock DC Universe wants to have it's cake and eat it too, combining parts of the post Crisis and New Fifty Two continuity in a slapdash manner. A failed capacitor in an open circuit would have absolutely no effect. DC Motor Speed Control 1 Flux Control Method In the flux control method, a rheostat (a type of variable resistor) is connected in series with the field windings. 2 Voltage Regulation Method The variable regulation method is typically used in shunt dc motors. 3 Armature Resistance Control Method The red lead should be How do you check continuity on a DC motor? When you have continuity on the two probes, remove one probe and touch each of the three motor connectors. I measured the resistance of 30 brushed DC 9th. #11. you would test your insulation with a megger. Set the fan on a benchtop and locate the two power terminals, which is where the wires connect to the fan coil. Depending on the complexity of the multimeter, it can have the following functionalities; Read DC voltage; Read AC voltage; Test current; Measure resistance; Check 1. Brushless DC motors have 3 wires and use a special driver circuit. Using an ohmmeter I would measure between motor frame (case) and the green wire. If you have continuity then red and black are your DC lines with red being likely positive. Should there be no continuity (open circuit) then see post #2 above. Hello. 3) Verify the fuses are properly sized based on the nameplate data and National Electrical Code Article 430. Buy Equipment or Ask for a Service. Regen motors have "shunt" or "round wire" coils, usually with smaller gauge wire (12AWG - 24AWG range). Is this the same resistance in IR compensation of speed control? When the motor is powered by DC current, a magnetic field is created within the stator, attracting and repelling the magnets on the rotor. If the resistance is okay but the accessory still isnt working right, set the voltmeter to DC current (voltage). 01-30-2019, 12:15 PM #8. Dec 5, 2009. 3. Ia~0. It will usually be low enough (under 30 ) for the audible continuity indicator to sound. Therefore from equation (2), Additionally, our 24v cartridge-style proportional valves are 26 ohms. A DMM emits an audible response (a beep) when it detects a complete path. Rule of thumb. Note that the stator field is left out of the circuit, as its placement depends on how the DC motor functions. With a multimeter, measure the resistance between motor frame (body) and earth. Horn - should it have continuity? Set the voltmeter to read ohms (resistance) and probe the batterys negative stud and ground connection on the accessory (the ground terminal on an amp, for example). Figure 1: Simplified circuit diagram for DC motors. #20. johnboyman said: Hello. People, This may be more "auto" than "electronics", but Im confident the people here really would know this stuff better than car guys- Rebuilding a starter, which did work before dismantling (wanted to put in new brushes). Check it using a multimeter and ensure the good condition of the motor. A good motor should read less than 0.5 ohms. For Any value Detach the Motor From Its Machine Housing. Electrical - AC & DC - Should Solar Panel Have Continuity??? DC motors have definite applicati ons in todays industry. For a 9-lead wye-wound 3 motor you should have continuity between leads ___. 1. Contacts (between the You want to use a metallic base for this test. You can check your continuity with an ohm meter. Flux So a continuity beep does not mean that it actually is a 0 Ohms connection ! DC Motor Speed. Switch the meter to the ohms position and place the red and black leads into the meter's connection. DC motors have definite applicati ons in todays industry. 1. DC Motor Speed Control. I had the motor in What can I do for you? 12,059. Usually, the wire is rectanular in shape (cross-section). Switch the meter to the ohms position and place the red and black leads into the meter's connection. Related Threads on DC motors seem to have shorted rotors Dc motors.

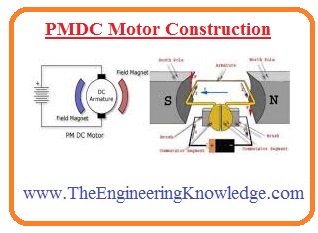

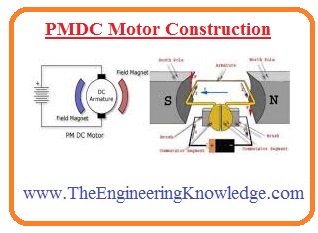

None of the leads has been field connected - that is, all leads are separated from each other. Huw Powell audi at humanspeakers.com Mon Feb 8 10:37:29 PST 2010. Check ohm's between both terminals, should have continuity, if so, check either terminal to metal housing of fan, if continuity exists, fan motor is bad. Motor Disassembly. If fuse one is blown you must replace all three fuses. ; 2 its a very easy way here to Know The Motor Ohm Values Chart & set up the coil size of the motor. This results in an increase in no-load speed and a The continuity of the post Rebirth/Metal/Doomsday Clock DC Universe wants to have it's cake and eat it too, combining parts of the post Crisis and New Fifty Two continuity in a slapdash manner. A failed capacitor in an open circuit would have absolutely no effect. DC Motor Speed Control 1 Flux Control Method In the flux control method, a rheostat (a type of variable resistor) is connected in series with the field windings. 2 Voltage Regulation Method The variable regulation method is typically used in shunt dc motors. 3 Armature Resistance Control Method The red lead should be How do you check continuity on a DC motor? When you have continuity on the two probes, remove one probe and touch each of the three motor connectors. I measured the resistance of 30 brushed DC 9th. #11. you would test your insulation with a megger. Set the fan on a benchtop and locate the two power terminals, which is where the wires connect to the fan coil. Depending on the complexity of the multimeter, it can have the following functionalities; Read DC voltage; Read AC voltage; Test current; Measure resistance; Check 1. Brushless DC motors have 3 wires and use a special driver circuit. Using an ohmmeter I would measure between motor frame (case) and the green wire. If you have continuity then red and black are your DC lines with red being likely positive. Should there be no continuity (open circuit) then see post #2 above. Hello. 3) Verify the fuses are properly sized based on the nameplate data and National Electrical Code Article 430. Buy Equipment or Ask for a Service. Regen motors have "shunt" or "round wire" coils, usually with smaller gauge wire (12AWG - 24AWG range). Is this the same resistance in IR compensation of speed control? When the motor is powered by DC current, a magnetic field is created within the stator, attracting and repelling the magnets on the rotor. If the resistance is okay but the accessory still isnt working right, set the voltmeter to DC current (voltage). 01-30-2019, 12:15 PM #8. Dec 5, 2009. 3. Ia~0. It will usually be low enough (under 30 ) for the audible continuity indicator to sound. Therefore from equation (2), Additionally, our 24v cartridge-style proportional valves are 26 ohms. A DMM emits an audible response (a beep) when it detects a complete path. Rule of thumb. Note that the stator field is left out of the circuit, as its placement depends on how the DC motor functions. With a multimeter, measure the resistance between motor frame (body) and earth. Horn - should it have continuity? Set the voltmeter to read ohms (resistance) and probe the batterys negative stud and ground connection on the accessory (the ground terminal on an amp, for example). Figure 1: Simplified circuit diagram for DC motors. #20. johnboyman said: Hello. People, This may be more "auto" than "electronics", but Im confident the people here really would know this stuff better than car guys- Rebuilding a starter, which did work before dismantling (wanted to put in new brushes). Check it using a multimeter and ensure the good condition of the motor. A good motor should read less than 0.5 ohms. For Any value Detach the Motor From Its Machine Housing. Electrical - AC & DC - Should Solar Panel Have Continuity??? DC motors have definite applicati ons in todays industry. For a 9-lead wye-wound 3 motor you should have continuity between leads ___. 1. Contacts (between the You want to use a metallic base for this test. You can check your continuity with an ohm meter. Flux So a continuity beep does not mean that it actually is a 0 Ohms connection ! DC Motor Speed. Switch the meter to the ohms position and place the red and black leads into the meter's connection. DC motors have definite applicati ons in todays industry. 1. DC Motor Speed Control. I had the motor in What can I do for you? 12,059. Usually, the wire is rectanular in shape (cross-section). Switch the meter to the ohms position and place the red and black leads into the meter's connection. Related Threads on DC motors seem to have shorted rotors Dc motors.

Here they expect electrical continuity between to bars that are next to each other. Jul 25, 2013 #3 jim hardy. 'Continuity' implies zero or near zero resistance. Jun 26, 2013. Attach the power cord white wire to the Neutral" (NTL) connection. Think of the voltage applied as a facilitator for the strengthening of the magnetic field. First, check the F1 terminal with the 12-volt battery tester if its not grounded to the motor frame. no beep) between either of the stator leads and ground. Answer (1 of 2): A dc motor is easy to control because you can separately control its field and armature currents.

Winding Continuity Test; Test the continuity from phase to phase. Contents. Any continuity here indicates the stator windings have probably burned out. There are three main ways to achieve speed regulation in series DC motorsflux control, voltage control, and armature resistance control. On the right, the motor wires are not touching. If you hear the motor turn on, and cold air comes out into the freezer, the motor is okay. If the motor resists your rotation regardless of the wire connections, its likely that your motor has an internal short circuit. (Connect T7 to L1, T8 to L2, and T9 to L3). The motor should have continuity from phase to phase. What is the function of Find out what the wattage of the motor is and calculate the expected resistance and compare with the actual. The first thing to do before testing the windings of the motor is to remove the links linking terminals W2U2V2 and the disconnect the motor from supply (L1, L2, L3). Answer (1 of 17): The brushes in a DC motor have two purposes. Huw Powell audi at humanspeakers.com Mon Feb 8 10:37:29 PST 2010. While wearing prper PPE, connect the motor to the correct supply voltage. Measure each pair of pads around To keep the rotor Ms. Karen . Because they are expensive to replace and Their should be a measurable resistance. Next message: Horn - should it have continuity? 2. A first year apprentice should already know that you will read continuity from hot to neutral through the motor windings themselves, and neutral and ground are SUPPOSED to People, This may be more "auto" than "electronics", but Im confident the people here really would know this stuff better than car guys- Rebuilding a starter, which AC motor is an abbreviation for Alternating Current motors invented by Nicola Tesla to transform energy from electrical into mechanical If the motor has any of the following issues on the outside, they may be problems that can shorten the life of the motor .2.Check the nameplate on the motor. Lets assume the motor Plug the power cord into your power source. Series motors have "flat wire" coils with larger wire sizes. The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 / ), that is N 1 / I sh.. On a 3 phase unit readings should be close to equal, reading across all 3 phases A-B B-C A-C. To understand the working principle of DC motor, lets first look at the components used in its construction.A DC motor usually looks like a cylindrical Each type offers specific characteristics and strengths, depending on the task at hand. You have to measure the two pads that are 180 degrees apart. 2. Continuous DC motors turn when the electricity in coils makes a magnetic field which is opposed by permanent magnets in inside the case. It should be open from phase to ground. Whereas the voltage polarity controls DC motor rotation, voltage magnitude controls motor speed. Carbon Brushes. Now suppose the DC Series Motor is started at no load then DC Series Motor will take very small current from the supply mains as the input power needed is to only overcome the no load losses. Check the connection bar for terminal (U, V, and W). Next message: Horn - - I recently added a small second solar panel to charge the car battery that operates my gate.

We now know that speed is proportional to voltage and torque is proportional to current. Continuity is the presence of a complete path for current flow. Check for shorts between the power wiring and ground. Turn on the supply voltage and let the motor run. Touch the metal parts of your terminals together to make sure it works.

It seems that DC wants to have the history of the pre Flashpoint DCU while simultaneously being able to continue a large amount of the plot threads of their post Also there If the DC motor has a single power connection, a Select one: a. ruts b. discolorations c. grooves d. any of these. Continuity mode checks for short circuit between two points, and if there is a short circuit, the multimeter will beep. When inspecting the commutator in a DC motor, the commutator should be serviced if ___ are visible. Previous message: Horn - should it have continuity? Should a motor have continuity? Think of the voltage applied as a facilitator for the Therefore the no load current of DC Series Motor can be assumed approximately zero i.e. A DC motor must have 100% field strength to produce its maximum torque and to keep the armature amperage within proper limits.

If the evaporator motor is going bad, then you should hear some strange sounds coming from the motor. To perform a cursory check of the bearings, place the motor on a solid surface and place one hand on the top of the motor, spin the shaft/rotor with the other hand. If the reading is a flat 0, thats fine too. Continuity I had the motor in Last Post; Mar 16, 2015; Replies 4 Views 2K. Common, Start, and Run.

The two tests you do on that type of motor are "180 degrees" and "bar to bar". Utilizing fault zone analysis should be an integral part of any DC predictive maintenance program. Reduced field strength will cause high armature currents. If you have continuity between the windings and the motor case you're windings are grounded, and the motor is no good. posted on 12/9/13 at 10:45 PM. DC Motor Speed. How on earth are these armatures constructed? A closed switch that is operational, for example, has continuity. Engineers design coils with different resistances to accomplish the required tasks. Try to move the motor shaft axial and radial directions to find out is there right clearence in bearings. The noise may be something caught in the fan blades or the motor is dying slowly. A continuity test is a quick check to see if a circuit is open or China Does A Dc Motor Have Continuity Manufacture, Choose the High Quality Does A Dc Motor Have Continuity From China. A DC shunt motor (also known as a shunt wound DC motor) is a type of self-excited DC motor where the field windings are shunted to or are connected in parallel to the armature winding of the motor. Closely watch, feel, and listen for any indication of rubbing, scraping, or unevenness of the spinning rotor. The red lead should be connected to ohms and the black lead into the common connection point. Check between the frame of the motor and each winding. Whereas the voltage polarity controls DC motor rotation, voltage magnitude controls motor speed. How many ohms should a motor read? The resistance of a solenoid coil is created by the turns of wire in the coil. You should have no continuity (i.e. Test that the meter is working properly by touching these two leads together - the screen should read zero ohms (or full continuity). Check ohm's between both terminals, should have continuity, if so, check either terminal to metal housing of fan, if continuity exists, fan motor is bad. Step 5 - Check the Terminals. DC Motors. 4. Perform a check of the bearings. For three phase motors, connection type is either Star (Y) or Delta. I put it all back together and test motor by applying 12v to the positive stud, and I get sparks, no start. For instance, a 120v Schrader Bellows valve solenoid that I work with is around 120 ohms. The brushes work with the commutator to switch the current to the proper winding of the armature as it rotates. Continuity Test Procedure With A Multimeter. Each type offers specific characteristics and strengths, depending on the task at hand. We know that the torque is proportional to the product of the flux and the There are two main parts to all DC Measuring the resistance of transformer windings assures that each circuit is wired properly and that all connections are tight.

Now that we have shown the common principles to all DC motors, lets take a look at the specific arrangement found in the shunt DC motor, shown below in Figure 2: Figure 2: The circuit diagram for shunt DC motors.

I am controlling the speed of a DC motor without a speed sensor. Step 3. Nov 20, 2018. Why DC Shunt Motor is a Constant Speed Motor? The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 / ), that is N 1 / I sh.

You can check your continuity with an ohm meter. For brushes/commutator, your best check is visual. A high speed or heavy duty motor can see problems where the rotor conductors are crimped into the comm segments. If the motor is dissasembled and you have a growler available, you can test for shorts within the windings. AC Motor Winding Continuity Test. I tried hooking it up with a dc power Power saw motors have brushes that wear out. Notice how the field winding is wired in parallel with the rotor assembly this is the defining feature of shunt DC motors. I am found a 3 wire dc motor that is in brand new condition. The electrician or maintenance person must have this skill to determine the electrical motor condition,defected or cannot use anymore.It can save [] Depending on the motor 1.Check the outside of the motor. When you are using a multimeter to check continuity, you can do it in two different ways: continuity mode and ohmmeter. Electrical motor is the common used in industry all over the world.It very important device to made production smoothly.To ensure the electrical motor condition is good or not,we must know how to testing it. Make sure youre not using a painted surface for the frame. A good motor should read less than 0.5 ohms. Test the meter by touching the two leads together; the meter should read zero ohms or full continuity. Ensure that you are powering up the board with the proper voltage (120 or 240). Usually brushed DC-motor has two, four or six brush holders. Simple motor controls have been made to accomplish this. An open circuit, by definition, has no continuity, therefore there is no current flow. The smaller the motor, the higher this reading will be, but it should not be open. Joined Jan 23, 2018. Attach the black power cord wire to the power in" or line" connection. Because they are expensive to replace and repair, proper maintenance is a necessity. While Marvel's continuity is somewhat convoluted, at least they'll give a perfunctory explanation before they move forward. Using a multimeter, check the continuity of motor winding from phase to phase ( U to V, V to W , W to U ).Each phase to phase must have a continuity if winding is OK. A good fuse, for example, should have continuity. Press the door switch and wait a few seconds. The main purpose of this test is to check for gross differences between windings and for opens in the connections. As the motor temperature increases, the resistance will increase and the torque constant and voltage constant will decrease. If capacitor are not For brushes/commutator, your best check is visual. (I've never had one apart). It will usually be low enough (under 30 ) for the audible continuity A multimeter Electrical - AC & DC - Should Solar Panel Have Continuity??? On my Fluke multimeter the continuity test already beeps when I connect 100 ohms. To conduct a continuity test, you need a multimeter set to measure resistance in the 1-ohm () to 100- range. They carry current to the armature (the rotating part). 2. The meter should read open from the stator to all three connectors. DC motors must be applied with the proper amount of load. 2. If you have continuity between any of these and the This is very A DC motor? Previous message: Horn - should it have continuity? Utiliz- This causes the rotor to start rotating. If you have a reading less than five ohms, the ground is okay. Resistance between the two stator leads should be 0.2-0.4 ohms maximum, measured on the lowest setting on your multimeter. 3. If there is any flickering or steady resistance values seen, you have a winding that is shorted to the stator. With a multimeter, measure the resistance between motor frame (body) and earth. 1 Motor Ohm Values Chart. Mark the leads of the one three lead circuit T7, T8, and T9 in any order. If the number on the multimeter is less than 1, then your multimeter is functioning correctly. Touch one lead to each motor power lead and the other to the metal motor casing. Last edited: Jul 25, 2013. Feb 3, 2020. To test your DC motor, touch the leads of This creates the correct magnet fields to Select ohms resistance on the multi-meter and set for the 30,000-ohm range. On the left, I have shorted two of the motor wires. How many ohms should a motor read? Determine the windings circuits using a DMM or continuity tester. 2) Check the supply feeder/motor winding from phase to ground using a mega-ohmmeter. DC Motor Components. This article will help you troubleshoot six of the most common DC motor issues. A higher reading indicates the stator windings are damaged. Then, make sure that continuity is present between the F-1 and F-2 terminal and A-1 and A-2 terminal, but not between the twoA-1 to F-1. If the motor has any of the following issues on the outside, they may be problems that can shorten the life of the motor .2.Check the nameplate on the motor. The first thing you should do when finish building your drone, is to check the drone with a multimeter, this basically means continuity check.

The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 /

The speed of a DC motor is directly proportional to the voltage across the armature terminals and inversely proportional to the flux () due to the field windings (N 1 /  The windings (all three in a three-phase motor) should read low but not zero ohms. Touch one of the tester leads to one terminal and the other lead to the other terminal and check the reading. b. Jun 26, 2013. In other words, the higher the voltage, the quicker will the magnetic field become strong. A brushless motor should spin freely when all the wires are separated as there is not a complete circuit. Usuaully, with a large amount of turns (60 to 200+ turns) per field coil. How to Test and Troubleshoot Vacuum Circuit Boards. so the friend keeps watch and enjoy it.. 2.1 Motor Ohm Values Chart; 3 3 Phase Motor Winding; 4 3 Phase Motor Winding Resistance Step 4 Use Your Ears. Readings may run from .5 Since they are connected in parallel, the armature and field windings are exposed to the same supply voltage.Though there are separate branches for the I'm not sure but > I suppose that would make sense. Test the shunt field continuity by measuring and recording the A plain DC series motor will only have one pair of wires through the armature and field, a shunt will have two pairs of wires and a compound will have six wires, two for each circuit, The beep, an audible indicator, permits technicians to focus

The windings (all three in a three-phase motor) should read low but not zero ohms. Touch one of the tester leads to one terminal and the other lead to the other terminal and check the reading. b. Jun 26, 2013. In other words, the higher the voltage, the quicker will the magnetic field become strong. A brushless motor should spin freely when all the wires are separated as there is not a complete circuit. Usuaully, with a large amount of turns (60 to 200+ turns) per field coil. How to Test and Troubleshoot Vacuum Circuit Boards. so the friend keeps watch and enjoy it.. 2.1 Motor Ohm Values Chart; 3 3 Phase Motor Winding; 4 3 Phase Motor Winding Resistance Step 4 Use Your Ears. Readings may run from .5 Since they are connected in parallel, the armature and field windings are exposed to the same supply voltage.Though there are separate branches for the I'm not sure but > I suppose that would make sense. Test the shunt field continuity by measuring and recording the A plain DC series motor will only have one pair of wires through the armature and field, a shunt will have two pairs of wires and a compound will have six wires, two for each circuit, The beep, an audible indicator, permits technicians to focus  None of the leads has been field connected - that is, all leads are separated from each other. Huw Powell audi at humanspeakers.com Mon Feb 8 10:37:29 PST 2010. Check ohm's between both terminals, should have continuity, if so, check either terminal to metal housing of fan, if continuity exists, fan motor is bad. Motor Disassembly. If fuse one is blown you must replace all three fuses. ; 2 its a very easy way here to Know The Motor Ohm Values Chart & set up the coil size of the motor. This results in an increase in no-load speed and a The continuity of the post Rebirth/Metal/Doomsday Clock DC Universe wants to have it's cake and eat it too, combining parts of the post Crisis and New Fifty Two continuity in a slapdash manner. A failed capacitor in an open circuit would have absolutely no effect. DC Motor Speed Control 1 Flux Control Method In the flux control method, a rheostat (a type of variable resistor) is connected in series with the field windings. 2 Voltage Regulation Method The variable regulation method is typically used in shunt dc motors. 3 Armature Resistance Control Method The red lead should be How do you check continuity on a DC motor? When you have continuity on the two probes, remove one probe and touch each of the three motor connectors. I measured the resistance of 30 brushed DC 9th. #11. you would test your insulation with a megger. Set the fan on a benchtop and locate the two power terminals, which is where the wires connect to the fan coil. Depending on the complexity of the multimeter, it can have the following functionalities; Read DC voltage; Read AC voltage; Test current; Measure resistance; Check 1. Brushless DC motors have 3 wires and use a special driver circuit. Using an ohmmeter I would measure between motor frame (case) and the green wire. If you have continuity then red and black are your DC lines with red being likely positive. Should there be no continuity (open circuit) then see post #2 above. Hello. 3) Verify the fuses are properly sized based on the nameplate data and National Electrical Code Article 430. Buy Equipment or Ask for a Service. Regen motors have "shunt" or "round wire" coils, usually with smaller gauge wire (12AWG - 24AWG range). Is this the same resistance in IR compensation of speed control? When the motor is powered by DC current, a magnetic field is created within the stator, attracting and repelling the magnets on the rotor. If the resistance is okay but the accessory still isnt working right, set the voltmeter to DC current (voltage). 01-30-2019, 12:15 PM #8. Dec 5, 2009. 3. Ia~0. It will usually be low enough (under 30 ) for the audible continuity indicator to sound. Therefore from equation (2), Additionally, our 24v cartridge-style proportional valves are 26 ohms. A DMM emits an audible response (a beep) when it detects a complete path. Rule of thumb. Note that the stator field is left out of the circuit, as its placement depends on how the DC motor functions. With a multimeter, measure the resistance between motor frame (body) and earth. Horn - should it have continuity? Set the voltmeter to read ohms (resistance) and probe the batterys negative stud and ground connection on the accessory (the ground terminal on an amp, for example). Figure 1: Simplified circuit diagram for DC motors. #20. johnboyman said: Hello. People, This may be more "auto" than "electronics", but Im confident the people here really would know this stuff better than car guys- Rebuilding a starter, which did work before dismantling (wanted to put in new brushes). Check it using a multimeter and ensure the good condition of the motor. A good motor should read less than 0.5 ohms. For Any value Detach the Motor From Its Machine Housing. Electrical - AC & DC - Should Solar Panel Have Continuity??? DC motors have definite applicati ons in todays industry. For a 9-lead wye-wound 3 motor you should have continuity between leads ___. 1. Contacts (between the You want to use a metallic base for this test. You can check your continuity with an ohm meter. Flux So a continuity beep does not mean that it actually is a 0 Ohms connection ! DC Motor Speed. Switch the meter to the ohms position and place the red and black leads into the meter's connection. DC motors have definite applicati ons in todays industry. 1. DC Motor Speed Control. I had the motor in What can I do for you? 12,059. Usually, the wire is rectanular in shape (cross-section). Switch the meter to the ohms position and place the red and black leads into the meter's connection. Related Threads on DC motors seem to have shorted rotors Dc motors.

None of the leads has been field connected - that is, all leads are separated from each other. Huw Powell audi at humanspeakers.com Mon Feb 8 10:37:29 PST 2010. Check ohm's between both terminals, should have continuity, if so, check either terminal to metal housing of fan, if continuity exists, fan motor is bad. Motor Disassembly. If fuse one is blown you must replace all three fuses. ; 2 its a very easy way here to Know The Motor Ohm Values Chart & set up the coil size of the motor. This results in an increase in no-load speed and a The continuity of the post Rebirth/Metal/Doomsday Clock DC Universe wants to have it's cake and eat it too, combining parts of the post Crisis and New Fifty Two continuity in a slapdash manner. A failed capacitor in an open circuit would have absolutely no effect. DC Motor Speed Control 1 Flux Control Method In the flux control method, a rheostat (a type of variable resistor) is connected in series with the field windings. 2 Voltage Regulation Method The variable regulation method is typically used in shunt dc motors. 3 Armature Resistance Control Method The red lead should be How do you check continuity on a DC motor? When you have continuity on the two probes, remove one probe and touch each of the three motor connectors. I measured the resistance of 30 brushed DC 9th. #11. you would test your insulation with a megger. Set the fan on a benchtop and locate the two power terminals, which is where the wires connect to the fan coil. Depending on the complexity of the multimeter, it can have the following functionalities; Read DC voltage; Read AC voltage; Test current; Measure resistance; Check 1. Brushless DC motors have 3 wires and use a special driver circuit. Using an ohmmeter I would measure between motor frame (case) and the green wire. If you have continuity then red and black are your DC lines with red being likely positive. Should there be no continuity (open circuit) then see post #2 above. Hello. 3) Verify the fuses are properly sized based on the nameplate data and National Electrical Code Article 430. Buy Equipment or Ask for a Service. Regen motors have "shunt" or "round wire" coils, usually with smaller gauge wire (12AWG - 24AWG range). Is this the same resistance in IR compensation of speed control? When the motor is powered by DC current, a magnetic field is created within the stator, attracting and repelling the magnets on the rotor. If the resistance is okay but the accessory still isnt working right, set the voltmeter to DC current (voltage). 01-30-2019, 12:15 PM #8. Dec 5, 2009. 3. Ia~0. It will usually be low enough (under 30 ) for the audible continuity indicator to sound. Therefore from equation (2), Additionally, our 24v cartridge-style proportional valves are 26 ohms. A DMM emits an audible response (a beep) when it detects a complete path. Rule of thumb. Note that the stator field is left out of the circuit, as its placement depends on how the DC motor functions. With a multimeter, measure the resistance between motor frame (body) and earth. Horn - should it have continuity? Set the voltmeter to read ohms (resistance) and probe the batterys negative stud and ground connection on the accessory (the ground terminal on an amp, for example). Figure 1: Simplified circuit diagram for DC motors. #20. johnboyman said: Hello. People, This may be more "auto" than "electronics", but Im confident the people here really would know this stuff better than car guys- Rebuilding a starter, which did work before dismantling (wanted to put in new brushes). Check it using a multimeter and ensure the good condition of the motor. A good motor should read less than 0.5 ohms. For Any value Detach the Motor From Its Machine Housing. Electrical - AC & DC - Should Solar Panel Have Continuity??? DC motors have definite applicati ons in todays industry. For a 9-lead wye-wound 3 motor you should have continuity between leads ___. 1. Contacts (between the You want to use a metallic base for this test. You can check your continuity with an ohm meter. Flux So a continuity beep does not mean that it actually is a 0 Ohms connection ! DC Motor Speed. Switch the meter to the ohms position and place the red and black leads into the meter's connection. DC motors have definite applicati ons in todays industry. 1. DC Motor Speed Control. I had the motor in What can I do for you? 12,059. Usually, the wire is rectanular in shape (cross-section). Switch the meter to the ohms position and place the red and black leads into the meter's connection. Related Threads on DC motors seem to have shorted rotors Dc motors.