since I have a 19,000 gallon pool, a turn over will take 19,000 / 3600 = 5.27 hours - or just over 5 hours 15 minutes (assuming the pump is up to the 60 GPM). First off is testing the 2 wire speed sensor. I wired a 2 speed 3 phase motor with a rotary cam 6 stage switch. Then attach it to the switchs center terminal. How do you test a 2 speed motor winding?

Determine the location of the black power supply line. During this test, a technician applies a high-frequency AC voltage to the motor, which in turn produces a magnetic field around the windings.  ECM motors are dual voltage motors capable of operating in 120 or 240VAC systems. Check the cooling fan. Durable steel construction ensures lasting use.

ECM motors are dual voltage motors capable of operating in 120 or 240VAC systems. Check the cooling fan. Durable steel construction ensures lasting use.  Unplug the motor from its power source. Access the connections between the power cord and the motor windings. Your Price: $435.00. To begin, set the multimeter to read ohms and then test the motors wires and terminal. 3. Line 3 to motor terminal 3. To test your motor for short to ground, youll need to set the multimeter to ohms and disconnect the motor from its power source. testing a single phase 5 lead 115v general electric 1/2hp 1740 rpm motor This may restore motor operation. Cover with three separate wire nuts.

Unplug the motor from its power source. Access the connections between the power cord and the motor windings. Your Price: $435.00. To begin, set the multimeter to read ohms and then test the motors wires and terminal. 3. Line 3 to motor terminal 3. To test your motor for short to ground, youll need to set the multimeter to ohms and disconnect the motor from its power source. testing a single phase 5 lead 115v general electric 1/2hp 1740 rpm motor This may restore motor operation. Cover with three separate wire nuts.

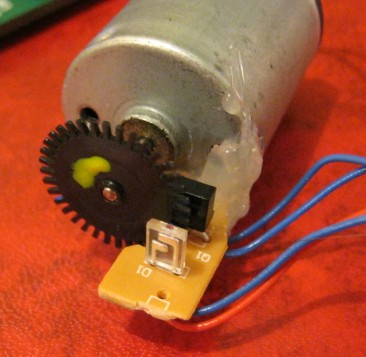

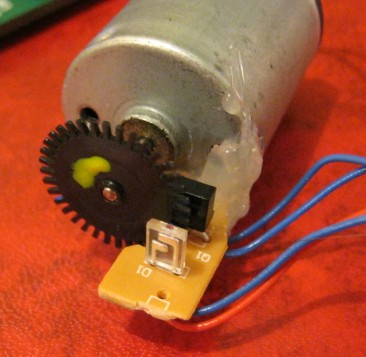

Connect the wires in the following manner. How do you know if your scooter motor is bad? We include wiring tables showing the circuit ampacity and wire sizes needed for electric motor circuits including for long wiring runs. EASA Senior Technical Support Specialist The most common method of load testing motors is dynamometer testing. It should be greater than 300V. Single Phase Electric Motor Wiring Tutorial: Baldor, WEG, Leeson. Additionally, all motors running on a VFD (even at 60 HZ) will lose service factor and be rated at 1.00. You should test the windings for a short to ground in the circuit and open or shorts in the windings. So this allows for forward and reverse with low and high speed. The speed of an AC motor depends on the frequency of the input power and the number of poles for which the motor is wound. The 3 wire speed sensor is externally powered, so you will need a power source of some form. Yokogawa entered the power business with the release of the EBS Electric Control System. 2-wheel rear drive motor. ) You should then rotate the motor shaft manually in order to examine its bearing condition.

Electric motor horsepower: this article explains how to calculate the horsepower of an electric motor if we know its wattage or current draw in amps.

Power Supply Test. For three phase motors, the expected voltage for a 230/400V system is 230V phase to neutral and 400V between each of the three phase supply lines. Check that the correct voltage is applied to the motor using a multimeter. Ensure the terminal for power supply is in good condition. Pickup. On the 120VAC systems, there should be a jumper between terminals one and two. Verify if electricity is being conducted through the extension cable. Check nearby stores. This test provides a DC voltage to the motor winding and measures how much current flows through the insulation to ground: 1) Test the motor de-energized by using a properly working voltmeter. Remove the cap and discharge it with a piece of metal like a screwdriver. Inspect by Sight, Touch, and Smell: Get your snout close to the speed manager and motor and smell them. Battery. My question is how doe I The HP shown on the nameplate are in the ratio of , if so, connect: LOW SPEED ( Lower HP) Line 1 to motor Terminal 1. Close. Electrical - AC & DC - Wiring hook ups for a 2-speed electric motor - Hi, I want to wire a 2-speed 1.5 HP motor to do the following: Hot tub duty. Weight: 3. Electric Motors Bureau of Energy Efficiency 26 2.3 Motor Characteristics Motor Speed The speed of a motor is the number of revolutions in a given time frame, typically revolutions per minute (RPM). Your child is sure to enjoy this fun toy. Step 2 is accurate DC Bus voltage measurement.

Label the three motor wires, making sure to continue to isolate them from one another, as 1, 2 and 3. Most problems with single-phase motors involve the centrifugal switch, thermal switch, or capacitor(s). Check nearby stores. Inspect the Motor Windings With a Multimeter. (Make some photos showing the connections so you can make them correctly again, if you need to take them apart.) If the reading is infinite, your motor should be fine. Protect against moisture with black electrical tape. Here are three ways to help find the cause of an AC motor problem. 1) Low speed to run thru a timer to heat tub via heat exchanger. Perform a runout check to detect deformations in the rotor. Practically speaking, to be able to measure the motors speed requires a power supply with high-performance built-in ammeter functions. Check around the outside of the motor and see if you can find a small button to press. With power disconnected and locked out, Ship to Store. Install the clamp-on ammeter to either the brown or blue wires at the motor inlet. Step 3: Check for Shorts and Opens. TOP DEAL. Step 3 is accurate measurement of motor input power / PWM variable frequency drives (VFD) output power. Check each wire, including T1, T2, T3 and the ground wire. The newly released L5+ Electric Scooter is a big-sized, performance scooter with an 8" polyurethane-filled front wheel, a solid rear wheel, and a highly efficient motor. Slow as 300 rpm means gearmotor or sophisticated driver for dc motor. A Universal Electric Motor is designed to operate on either alternating current or direct current (AC/DC). You should be looking for burns, any damage to the body, the shaft or cooling fan. In this article, we will address the reasons for performing load tests as well as methods of load testing motors. Do the following for a single-phase motor: Assess motor appearance. Check C to E, S to E, R to E. Minimum test value for a good electric motor is at least 1M With the motor running, check the full load amps (FLA) with a suitable meter or preferably a clamp on meter and compare with the motor name plate FLA. Deviations from rated FLA could signify problems with the motor under test. use the multimeter to measure the resistance of each winding leg. Inspect the Motor Windings With a Multimeter. 1. Step 1 is accurate measurement of three-phase input power to the variable frequency drive (VFD). If the problem is in the centrifugal switch, thermal switch, or capacitor, the motor is usually serviced and repaired. Also try on the higher ohms settings on the meter. The enclosed version comes with a rugged housing, power on/off switch, power on indicator lamp, front access fuse, as well as convenient input and output cords and plugs. If the motor is less than 1/8 HP, it is almost always replaced. Further details on dynamometer testing are given in Tech Note 5 "Dynamometer Testing Electric Motors," which can be found in the EASA

After about a minute the motor clicks (CB or relay) then you can turn the motor on again and it does the It is a NEMA L5-30P to RV Marine Style NEMA L5-30R. The high-speed connection of the motor should then be connected to the switch. It is connected directly to the power source. If you do not see a service factor rating on the motor nameplate the service factor is typically 1.00. Step 2: Connecting the Supply Line. Make sure it is of a rating above that are responsible. Minimum test value of the electric motor is 1 Meg Ohm (1 M) With the motor running, check the running amps of the motor using a Clamp on the meter. Welcome to My Activity. If you get a zero reading or any continuity reading, you have either a motor problem or a cable problem. Step 2 is accurate DC Bus voltage measurement. The Monster Jam Grave Digger 24-volt Battery-Powered Ride-On is ideal for any fan. 98. Tom Bishop, P.E. Use a pair of pliers to detach both wires. Ammeter.

Add to cart. The article gives a simple formulat to convert electrical amps to horsepower and explains what data Now the problem I have is that if you select forward low speed the motor runs in the correct direction but when I select forward high speed the motor runs with the higher speed but in reverse. Secure L3 to T3 and T5. The Monster Jam Grave Digger 24-volt Battery-Powered Ride-On is ideal for any fan. Step 4 Test the lead. Remove the junction box cover plate, if there is one. Availability: Out of Stock. AC Motor Winding Continuity Test. Check it using a multimeter and ensure the good condition of the motor. 2. Your child is sure to enjoy this fun toy. 2. The service factor is expressed as a decimal. In order to effectively test the motor, you will be required to disconnect it from the power supply. Your tester will have two wires with lead tips. Check the connection bar for terminal (U, V, and W). Please consult your manual for more information. How To Wire a PE154 Digital Timer to a 2 Speed 230v Motor. Replacement motor for a new or existing evaporative cooler. Remember that Kia Motors America, Inc. Push the lock button on your key fob for three seconds, until the lights on your dashboard blink. 2) Place both instrument test leads to ground and verify a solid connection to ground of the instrument lead. So check their performance, the engine is the one that bought and is in good condition. If possible, disengage the load. 3 Things to Test with a Circuit Tester. First, check for proper high-voltage and ground at the five-pin connector at the motor. Then, using a red wire, connect the switch to the motors low-speed contact. Line 2 to motor terminal 2. 1959-1960-1961-1962 Chevy Two Speed Electric Wiper Motor with Pump Hardtop, Sedan, Impala, Bel Air, Biscayne. Apparently had multiple competing offers from FB LinkedIn Netflix. Set your multimeter to Ohms. Touch the leads of the meter to the leads on the cap and the reading should rise from zero to infinity; if you don't see this, discharge the cap and try again with the test leads reversed on the cap. Two-speed design lets you optimize cooling comfort. Make sure its set to measure volts as a multimeter. Repeat this process with terminals 2 and 3 and 1 and 3. Any mechanism that look burned or melted, or that smell like burned plastic are approximately always imperfect and should be replaced. Step 1 is accurate measurement of three-phase input power to the variable frequency drive (VFD). Alternatively, if you get a reading of 0, you might have a cable issue. In the appropriate cells and the necessary capacity. So this allows for forward and reverse with low and high speed.

In this type of motor, a 2:1 relationship between the low and high speed must exist. If motor brush and com type control can be rheostat which means variable resistor but way inefficient! Each wire should have a plastic end going to the power supply. google. Should use pwm or phase control! It is a series wound motor. Synopsis: Daymak Boomerbeast 2 is the first all terrain electric mobility scooter with fast It is provided with a field winding on the stator which is connected in series with a commutating winding on the rotor. Alternatively, if you get a reading of 0, you might have a cable issue. 1. Horsepower (hp): .5 hp. The Circuit breaker on the house is not popping anymore. How to Get It. Each winding will give you nearly equal value to each other. Complete testing of a motor and drive system is a four-step process. It is not complicated to install as it just unbolts and there is a fork to engage, then top off will oil.

Check from phase to phase (U to V, V to W, W to U) and 2. check from phase to earthing (U to E, V to E, W to E). Hi Nick, the last two speed actuator motor that I purchased was about $79.00 for an Eaton axle. Now connect your voltmeter to an AC range and connect two of the wires to terminals 1 and 2. Commonly manufactured in fractional horse-power sizes. Compare against the value on the chart. Now the problem I have is that if you select forward low speed the motor runs in the correct direction but when I select forward high speed the motor runs with the higher speed but in reverse. The idea is to match supply voltages and load impedances so as to balance the three legs. After all of the connections are made, the following code can be uploaded to the Arduino to control the speed of the motor: // Include the servo library #include // Create a servo instance Servo servo1; void setup () { servo1.attach (9); // Set the shorts between the power wiring and ground. Single Phase Electric Motor Wiring Tutorial: Baldor, WEG, Leeson. 2-wheel rear drive motor. ) Winding Continuity Test; Test the continuity from phase to phase. The Hipot Test for Dielectric Strength: Determining Efficacy of Cable Insulation. Delivering to: 60607 |. 1. The value should be equal to the source voltage. Take the black multimeter standard test lead and touch the white wire with it. I wired a 2 speed 3 phase motor with a rotary cam 6 stage switch. How do you test a two speed motor? You should test the windings for a short to ground in the circuit and open or shorts in the windings. I know I need a double pole single throw switch. Check the calibration of the balancing machine. Measure voltage between terminals 2 and 3. Touch and continue touching the white brown wire with the red multimeter probe. When turning the motor on high, it would run for a second, then cutoff. All models feature single-phase AC input and fully variable AC output. Step Two. 98. Verify motor winding resistance. 18 Gauge American-Made Hook-Up Wire (Corrosion resistant, top quality. However, if the motor is more than 10 years old and less than 1 HP, the motor is usually replaced. 2) Hi speed thru a switch. This is usually a safeguard against overheating. Below are just a few of the many motor tests available. Two speed, single winding motors are of the design that is called consequent pole. Correct any voltage issues before proceeding. 3. The tools needed for testing either a 2 or 3 wire speed sensor are essentially a multimeter with the clamp leads, and a drill. Using your multimeter, check the voltage of each unit and see if they are up to the recommended voltage. Connect L2 to T2 and T4. Twist the three separate connections, one a time, with the wire pliers. 2.3.2 Open Loop System The Open Loop uses a speed control to vary the speed and torque of a motor to correlate Monster Jam 1:24 Collector Truck S2. Features 6. Reset the condition for the opposite speed and repeat. Values measured in this step should be around point one or point two ohms. Several sources give a simple formula for determining an electric motor's rotating speed: Select ohms resistance on the multi-meter and RUNNING TEST Electronic Start Switch Reconnect the connector to the motor inlet. 3. testing, similar testing can be completed using a motor with a control. With a speed control, a PMDC, BLDC, or AC motor can be used. During the load testing phase, it is import to understand what the load profile is and what type of cycle is associated with it. Winding Resistance Test; Test the resistance readings from phase to phase. A. Parts for Model 74598. These nice little speed controllers will control your single phase motors in either 120v or 240v. Cutting out wont rev past 3000 rpm under hard acceleration. View More Details. Leave motor terminals 4,5 & 6 open and insulated from each other. The inductance for each phase is then measured and compared to the other phases to calculate the motors inductive imbalance. daveydo said: what i call a rheostat device. 1. 18 Gauge American-Made Hook-Up Wire (Corrosion resistant, top quality. Performance is per the motor design, and speed and torque performance are not monitored. Set the voltage setting of the insulation resistance tester to 500V and check motor windings to earth. Add to cart. Monster Jam 1:24 Collector Truck S2. How do you troubleshoot a 3 phase motor? Attach L1 to T1 and T6. Check C to E, S to E, R to E. Minimum test value for a good electric motor is at least 1M Running Amps Test With the motor running, check the full load amps (FLA) with a suitable meter or preferably a clamp on meter and compare with the motor name plate FLA. Deviations from rated Check out for the rotation of a smooth and free shaft.

Here are a few other helpful resources for wiring a dual-speed Pump: How To Install a 2 Speed Motor and T106 Timer. If motor induction type, control needs be inverter drive (like VFD). Then inspect each wire and look for infinite readings. To begin, set the multimeter to read ohms and then test the motors wires and terminal. 2. Connect the electric cable to an electrical source. On 240VAC systems, the jumper should be removed. Then inspect each wire and look for infinite readings. Turn on the power unit, which supplies electricity to your small electric motor. If any phase fails the test, the motor is burnt; otherwise, the motor is good to go. Thank you for your answer. Complete testing of a motor and drive system is a four-step process. Simply pull it out. The second item to check is the battery pack. Using a multimeter, check the continuity of motor winding from phase to phase ( U to V, V to W , W to U ).Each phase to phase must have a continuity if winding is OK. (FAQs) Regarding How to Test Electric Scooter Motor Q. Compare the applied voltage with the capacitor's terminal voltage. Wind the drill at full speed again and note the AC voltage. 2. How to Wire the 18313301 Switch to 115 Flex-48 2 Speed Motor Check the motor winding resistance or ohms reading with a multimeter. Since there are three terminals S, C, R in a single phase motor, measure winding resistance: Any deviation signifies a possibly bad electric motor or a motor that requires repairs. Start by completely disconnecting the spindle motor from all power sources. How do you test a 2 speed motor winding? How To Wire the 1011431-001 Toggle Switch to a Century STS 2 Speed Motor. Parts for Model 74598. Is connected in series to the battery to measure Amps. For three phase motors, connection type is either Star (Y) or Delta. To test your motor for short to ground, youll need to set the multimeter to ohms and disconnect the motor from its power source. Take your multimeter and set it to ohms. TOP DEAL. Step 3 is accurate measurement of motor input power / PWM variable frequency drives (VFD) output power. This step will require a volt-ohm tester. If the electrical supply checks out, examine the motor itself. Start the motor. The second type of motor is the two speed, single winding motor. Make sure you check if electricity is transferring to the motor. Do a precision balancing according to the application, criticality, and characteristics of the motor. Weight: 3. Compare to the FLA on the nameplate of the motor. Inspect the coupling and cooling fan, verify its integrity and conditions. To test covers the following: ESC. As far as turnover - my sand filter says it can handle up to 50-60 Gallons / minutes - using 60 - this means it could put 3600 gallons per hour though it. Ballpeen, Your motor is one of the following types: Constant Torque 2 Speeds. For the next step, turn on your digital multimeter. Load Test. Measure the voltage between terminal 1 and 4. 2.3.1 Line Fed Motor Liner Fed is the most basic of all the motion control systems. Start the machine in the speed matching the condition and measure the amperage. Set the speed switch to low speed. Low speed will requrie c1= L1,L2,L3 powered by phase 1, phase 2, phase 3 of the primary source voltage.

ECM motors are dual voltage motors capable of operating in 120 or 240VAC systems. Check the cooling fan. Durable steel construction ensures lasting use.

ECM motors are dual voltage motors capable of operating in 120 or 240VAC systems. Check the cooling fan. Durable steel construction ensures lasting use.  Unplug the motor from its power source. Access the connections between the power cord and the motor windings. Your Price: $435.00. To begin, set the multimeter to read ohms and then test the motors wires and terminal. 3. Line 3 to motor terminal 3. To test your motor for short to ground, youll need to set the multimeter to ohms and disconnect the motor from its power source. testing a single phase 5 lead 115v general electric 1/2hp 1740 rpm motor This may restore motor operation. Cover with three separate wire nuts.

Unplug the motor from its power source. Access the connections between the power cord and the motor windings. Your Price: $435.00. To begin, set the multimeter to read ohms and then test the motors wires and terminal. 3. Line 3 to motor terminal 3. To test your motor for short to ground, youll need to set the multimeter to ohms and disconnect the motor from its power source. testing a single phase 5 lead 115v general electric 1/2hp 1740 rpm motor This may restore motor operation. Cover with three separate wire nuts.