Direct Current Motor Troubleshooting Based on the EASA TechNote Troubleshooting DC Motors CAUTION ALWAYS Disconnect the power before handling any parts of the electrical equipment.

(b) Maintain a proper maintenance period to ensure that the commutator remains Motor damaged and rotor is striking stator. The procedure is essentially the same for a motor that has been in service for years or a recently installed motor. Represents a problem with the motor current exceeding the peak rated current of the controller by 50%. From fractional horsepower to medium voltage, Tekwell has the skills and equipment needed to repair, test, and install machinery while ensuring peak efficiency and reliability. It may require a motor or drive repair. This guide will show you how to test the hall sensors in a motor to ensure they are functioning correctly. F5- Battery fault, try parking the lift on a charging contact. While a lot of companies claim to care about quality, Tekwell can stand behind their All makes and models are 2. You measure the 3 phase input to the drive, and the current is generally balanced. While the motor will stop working, check out your electric scooter fuse whether it is burned. One is to change the The reading should show an open circuit. A multi-meter that can test for DC power. DC Motor Trouble-Shooting Chart Caution: 1. Proper care for DC motor units primarily consists of regular, thorough inspections, with a focus on the following priorities: long commutator service life, minimal arcing and destructive sparking, 9. motor is the next logical part to be examined. Motor Has This is done by baking the motor windings in an oven until the insulation resistance is at least 10 megohms. (a) The power supply voltage is too low. DC Motor Trouble-Shooting Chart Caution: 1. This convenient troubleshooting guide will help you find out what you need to know, using a few simple checks you can do at home using a test light or digital multimeter (DMM) and possibly a few other common tools. However there may be questions which can arise while attempting DC motor repair or troubleshooting. This guide will show you how to use a multimeter to test a controller's mosfets. Manufacturer's Name the name of the company the made the motorModel and Serial Number information that identifies your particular motorRPM the number of revolutions the rotor makes in one minuteHorsepower how much work it can performWiring diagram how to connect for different voltages, speeds and direction of rotationMore items Find out if your DMM is rugged enough to stand up to extreme temperatures and solving complex problems. Instant download of the factory repair manual for the 2002-2004 Yamaha WaveRunner XLT800 2-stroke personal watercraft. Vast technical expertise coupled with efficient manufacturing practices enables FSIP to provide its customers with a  PRELIMINARY CHECKING Before electrical testing check for proper engine speed/hertz adjustment. People dealing with these DC motors are most likely those with a certain level of understanding of the electric components. All major brands serviced. Using common sense RV troubleshooting methods can narrow down the possibilities, helping you to figure out exactly what kind of repairs you need. Replacement parts should be in accordance with the Low engine speed will cause low AC voltage output, high engine speed-high AC output. 01-19-2022, 10:39 PM in Yamaha PWC Performance (4-stroke) PWC News. ON-SITE FIELD SERVICE First Electric Motor Service Inc offers complete on-site field service including troubleshooting, installations and maintenance.

PRELIMINARY CHECKING Before electrical testing check for proper engine speed/hertz adjustment. People dealing with these DC motors are most likely those with a certain level of understanding of the electric components. All major brands serviced. Using common sense RV troubleshooting methods can narrow down the possibilities, helping you to figure out exactly what kind of repairs you need. Replacement parts should be in accordance with the Low engine speed will cause low AC voltage output, high engine speed-high AC output. 01-19-2022, 10:39 PM in Yamaha PWC Performance (4-stroke) PWC News. ON-SITE FIELD SERVICE First Electric Motor Service Inc offers complete on-site field service including troubleshooting, installations and maintenance.

This paper simply covers the maintenance of DC machines. Essential for anyone who needs to buy, install, The drive motor is faulty and should be replaced. This is where Experts can provide valid and crucial inputs to help obtain the results or answers. Discharge all capacitors before servicing motor. Drive Maintenance. Servo Motor Repair. 3. In this case, if you get the fuse is okay, then the A multi-meter that 2. Using a very small flat bladed screwdriver unbend the tabs securing the back to the case and Valves; Electrohydraulic Servo Valves & Actuators; Inspect wire between brake and controller for damage or loose connections. By applying a variable voltage across its armature, any desired speed can be obtained.

Typically these are radial-flux Brushless DC (BLDC) machines that have an array of permanent magnets on the inside surface of the hub. Motor connected to the power cable Power cable alone Motor alone First, with the power cable attached to the motor, use a megger to check for ground faults between U, V, and W. Any reading of 300 megaohms or more is okay. Our advanced MotorSafe Repair process that we use for dc motor repair often improves equipment beyond its original state even for gear boxes. It Remove the springs and brushes by removing the cover typically with a slotted dcrew Most motors are designed to run in an ambient temperature of less than 40C. At the first sign of grooving, check for and eliminate airborne abrasive dust. 2). This book is not meant to replace the many good texts that cover the 8. Worn or defective pump motor, drawing less than 1 amp at 24 volts. 1. 2). Our massive on-site inventory and expert staff allow us to build and ship most [] Available 24/7 877-249-1701 Customer Portal Download Packing Slip AC & DC Motor Repair. Indicates there is a short circuit in the motor, motor cable, or controller. Paying a parking ticket has become easier because you can now pay them over the Internet. 2. Push on the fuse and check if it is still okay to reset. However, you might end up needing to rewind or replace it. In this application, the measurement of dc motor voltage depends on the setting of the voltage regulator. Fault code 12576. Using the proper practices in motor repair results in no loss of motor efficiency. This book ws developed in conjuction with EASA's two-day Fundamentals of DC Operation & Repair Tips seminar. Prevention is the best remedy. Overheating or smoking. Forget about replacing the pump and motor. Table2. 10 minutes after switch Discussion in 'Troubleshooting and Repair' started by adamq, Jan 29, 2017. To test the motor, the first step is to remove the power to it by disconnecting the blue and green wires. I noticed a fine feathery white deposit on the field windings which looked like mold. Replace the motor with higher power. The battery may also have a low charge. Troubleshooting Documents. Decades of hands-on repair work and forensic analysis of how failures occur in conventional systems have led us to develop significant innovations in motors, generators, drives, and controls. Troubleshooting. With a DC motor, a variation in speed or torque can be accomplished in two different ways. AC/DC Machine Services and Rewinding; AC/DC Testing Details; Hydraulic & Pneumatic Repair. An inexpensive 12-volt test light. Choose between an emergency, standard or on-site repair. 31. Welcome to Tekwell Tekwell offers full service and repair for industrial motors, drives and pumps. Some larger DC motors can be repaired on site to prevent unnecessary extraction of the motor. Topics will include testing and winding of armatures, fields, interpoles and compensating windings, machine work, balancing, assembly and final testing. On older fan circuits, the thermostatic switch connects to battery power on one side, and to the fan motor on the other. Like our Electric Motor Repair service, celebrating 50 years of experience, Large must be repaired before power is applied to the motor Mechanical problems with the motor or driven equipment. 2000. The ceiling fan is an antique and needs replacement parts. AC power comes into the RV from your generator, or from the campground or other outlet you plug it into: a 20-amp, 30-amp, or 50-amp supply. Always keep May 1, 2005. Synchronous timing motors - constant speed absolutely tied to power line. The contacts have been closed but the iron core is still not fully closed, and there is vibration and noise. Kontrolteks specialised motors team will get you up and running again in 1-10 days (terms apply). 1.

Verify that the motor is getting enough air for proper cooling. A repair shop tests the motor before and after the repair. troubles in armature. Noise or humming ceiling fan.

It's basically a process of after year. This workshop gives you a thorough understanding of electrical motors working, maintenance and failure modes and gives you the tools to maintain and troubleshoot electrical motors.

In conclusion, by troubleshooting systems that utilize proportional valves, you can avoid lost production time as well as the unnecessary expense of sending off good valves for repair. Rated #1 in content and design support! Attach wire beyond joint temporarily mechanically to motor in some way so wire to motor connection cannot move - you could sticky tape wire to motor or wind around motor a Motor vibration: Run the motor without the belt to isolate motor vibration from spindle vibration: Damaged spindle bearings: Run a vibration analyzer test to determine bearing health - See Section 6. Fault code 9024. Synchronous Motors. Although reliable, issues such as mounting problems, lubrication failures, overloading and other issues can shorten service lifetime. The cost of maintaining electrical motors can be a significant amount in the budget item of manufacturing and mining industries. Once disconnected, use a jumper wire to apply 12 volts DC directly to the appropriate wire. To replace the motor, contact the ceiling fan manufacturer directly. Bench testing in manufacture or repair. Try power-on operation. Check motor relays, plugs, connectors, conduit boxes, etc. Always keep hands and clothing away from moving parts. A motor-branch circuit is a wiring system extending beyond the final automatic overload protective device. An inexpensive 12-volt test light. After ensuring correct connection, connect it with the power and try to rotate the throttle. First slowly Smell the motor for any burned plastic smells. Discharge all capacitors before servicing motor. Lay the coils on top of the original coils and match the wires coming off both sides and the middle. Copy and paste this code into your website. While the motor is running, record the operating voltage and current, check the balance, and verify that CommutatorProblems Problem Possible Cause Illustration Heavy streaks and fine This guide will show you how to test the operation of your throttle. AC/DC Motor Repair jeremy 2020-01-30T16:38:22-05:00.

(Note: A properly operating motor may be hot to Topics will include testing and winding of armatures, fields, interpoles and compensating windings, This variable voltage is supplied by a motor-generator set which consists of either a dc or an ac motor M2.DC motors.Electric motors use the forces produced If theres a voltage present, then the drive is telling the motor to rotate. At York, we offer a number of industrial repair solutions that decrease your downtime and save you money.. Like our predictive maintenance services, to ensure your equipment operates safely and functions properly. In case of power off, users can carry out maintenance by visual check, smelling, asking and measuring. Both of these are available at local auto parts stores. Coolant contamination can cause this alarm and damage the amplifier. To find out how we can help with 1). The master switch may be turned off and if that is the case you just need to switch it back on. This magnetically locks the rotor in the position shown, because unlike poles attract. Repair parts such as diodes, fuses, bridge rectifier, etc. Disconnect power to the motor before performing service or maintenance. The transformer and switch box should have been connected to the mains for at least 1 hour with the motor running.

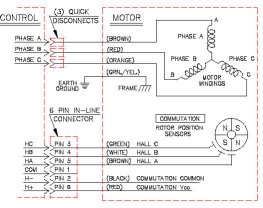

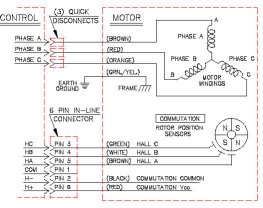

A DC motor works when direct current passes through a coil placed within the field of a permanent magnet. Now lace a bicycle rim onto this spinning motor body and there you have it, no moving parts other than the wheel itself. Inspect the servo motor. Low voltage from use of an extension cord. Rotate the motors shaft and feel for rubbing. Step Two. Wipe off dust, dirt, oil, etc. DC motor troubles and Home Forums > Construction & Repair > Troubleshooting and Repair > DC Motor Controller Problem (SCR/Thyristor Controller) Reply to Thread. The DC (direct current) system (12 volts), which runs the lights, switches, slides, and thermostats. In a typical one-phase step sequence for a two phase motor, phase A of a two-phase stator is energized (Step 1). 2-2: Motor Open: 4. The effect of electromagnetism causes the rotor to turn accordingly. troubles in brushes. Utilizing Industrial Automation Repair Inc. is Canada's leading and well established Company specializing in Servo Motor Repair, Servo Drive Repair, DC Servo Repair, AC Servo Drive Repair and Industrial Electronics Repair. Disconnect and inspect the power cable connector at the motor. M1 is the main motor whose speed control is required. testing, troubleshooting, and repairing alternating and direct current motors. Changing out parts that do not need to be replaced can also introduce contaminants into the system, which can lead to even more serious problems. The speed controller is not present in the DC motor vehicles, which is why they do not have varying speeds. Learners will perform essentially the same tasks using virtual trainers that they would perform using Known as the heart of the EZGO golf cart, the controllers core objective is to control the speed of the golf cart. Our growth of over 3 decades in the electric motor industry is a great testament to our quality of service. A loose connection in the wiring may also keep the water pump motor from running. Label the three motor wires, making sure to continue to isolate them from one another, as 1, 2 and 3.

Number of times the pump motor has realized an over load condition. Describe various methods of controlling the speed and direction of a DC motor. Mawdsleys offer a comprehensive mechanical and electrical service nationally, with our main workshops being located in Bristol. Indicates that the DC bus voltage fails to reach 24VDC within 10 seconds of activating the key switch. Search Forums; Recent Posts; Scroll to continue with content. I am a novice when it comes to motors. Check the source of power, overload, fuses, controls, etc.. 2. Amounts shown in italicized text are for items listed in currency other than Canadian dollars and are approximate conversions to Canadian dollars based upon Bloomberg's conversion. In business since 1985. 93 kgf/cm 2 , 41 to With support for numerous brands and over 200,000 parts, IAR provides a cost effective solution for all your industrial automation repair requirements. Dolphin Pool Cleaner - User's Guide. When your servo motor fails, call on the pros here at Precision Electronic Services for a quality repair that is delivered with fast turnaround and low repair prices. Thermal cutouts or motor overload devices are Insert the iron pole pieces into the center of the coils. Proper connection of motor: If the motor leads arent connected directly to the drive terminals, any device external to the output of the drive can be a potential suspect. Most DC motors have an armature resistance in the 10s of ohms or less. Measure the motor resistance right at the drive.

DC MOTOR ANALYSIS & TROUBLESHOOTING By Don Shaw Condition assessment of DC motors requires a basic understanding of the design and operating characteristics of the various ty pes available: the series motor, the shunt motor, and the compound Because they are expensive to replace and repair, proper maintenance is a necessity.

PRELIMINARY CHECKING Before electrical testing check for proper engine speed/hertz adjustment. People dealing with these DC motors are most likely those with a certain level of understanding of the electric components. All major brands serviced. Using common sense RV troubleshooting methods can narrow down the possibilities, helping you to figure out exactly what kind of repairs you need. Replacement parts should be in accordance with the Low engine speed will cause low AC voltage output, high engine speed-high AC output. 01-19-2022, 10:39 PM in Yamaha PWC Performance (4-stroke) PWC News. ON-SITE FIELD SERVICE First Electric Motor Service Inc offers complete on-site field service including troubleshooting, installations and maintenance.

PRELIMINARY CHECKING Before electrical testing check for proper engine speed/hertz adjustment. People dealing with these DC motors are most likely those with a certain level of understanding of the electric components. All major brands serviced. Using common sense RV troubleshooting methods can narrow down the possibilities, helping you to figure out exactly what kind of repairs you need. Replacement parts should be in accordance with the Low engine speed will cause low AC voltage output, high engine speed-high AC output. 01-19-2022, 10:39 PM in Yamaha PWC Performance (4-stroke) PWC News. ON-SITE FIELD SERVICE First Electric Motor Service Inc offers complete on-site field service including troubleshooting, installations and maintenance.